“If my car is automatic, it doesn’t have a clutch, right?”

Not quite. While automatic cars don’t have a clutch pedal, they still rely on a network of internal clutches to shift gears smoothly. Instead of a single friction disc like in a manual transmission, automatics use multiple clutch packs hidden inside the transmission. Each of these small clutches engages and releases to control different gear sets, creating seamless power delivery without any pedal work from the driver.

These automatic transmission clutches are vital to how your vehicle performs. They manage gear changes, absorb torque, and keep the ride smooth under all driving conditions. When they start to fail, you might notice slipping, harsh shifts, or strange noises that can quickly lead to major repair costs.

At FCC North America, we design and manufacture high-performance clutch systems that keep both manual and automatic transmissions running at their best. Understanding how the automatic transmission clutch works and what causes it to fail helps you make smarter decisions about maintenance and repair before small problems become expensive ones.

The Clutch in an Automatic vs. Manual Transmission

When it comes to how power moves from the engine to the wheels, manual and automatic transmissions take very different approaches. Both depend on a clutch system to manage that power transfer, but how each one works couldn’t be more different.

In a manual setup, the clutch is a single friction disc controlled directly by the driver through a pedal. In an automatic, the job is handled by several smaller clutches working together under precise hydraulic control. Understanding this difference makes it easier to see why automatics still need clutches and how their design affects performance and longevity.

The Manual Transmission (Single) Clutch

In a manual transmission, the clutch acts as a direct link between the engine and the transmission. When you press the clutch pedal, it disconnects engine power so you can shift gears smoothly. When you release it, the clutch re-engages and sends power back to the wheels.

You can think of the manual clutch like a light switch for the drivetrain. Press the pedal, and power flow is turned off. Release it, and everything turns back on. This simple setup gives the driver full control but also requires precise timing and skill to prevent wear or rough shifts.

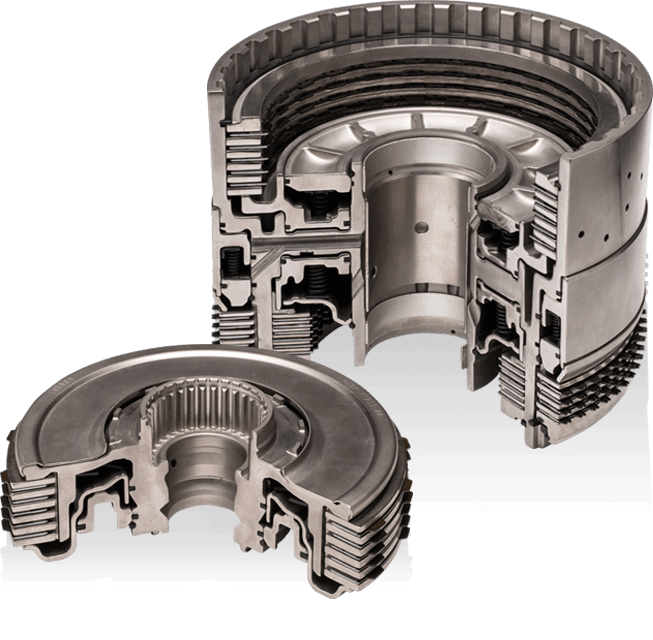

The Automatic Transmission Clutch Pack

An automatic transmission doesn’t use a single clutch disc like a manual. Instead, it relies on clutch packs, which are stacks of alternating steel and friction plates inside the transmission. Each pack connects or disconnects parts of the planetary gear set to create smooth, automatic shifts.

Think of these clutch packs as a group of smaller clutches that work together like tiny, precisely timed brakes. Hydraulic pressure from the transmission fluid pushes pistons that squeeze the plates together, locking certain components in place to select a gear ratio. When the pressure releases, the plates separate and free the next gear.

This setup lets the transmission shift automatically without driver input, delivering consistent performance and a smooth ride.

Looking to upgrade or replace your clutch components? Explore FCC’s precision-built clutch systems for lasting reliability and performance.

How Automatic Transmission Clutches Engage

Automatic transmissions are constantly balancing hydraulic pressure, timing, and friction to shift gears without the driver ever noticing. Every time your car changes gears, a series of internal clutches and bands activate or release in perfect sequence to control which gears are turning inside the transmission.

This section breaks down how those parts work together inside a transmission clutch system, showing how pressure, fluid flow, and mechanical movement combine to create a smooth, automatic shift.

Clutch Packs and Bands

Inside an automatic transmission, clutch packs and bands are the key players that make gear changes possible.

A clutch pack is a stack of steel and friction plates that engage when pressurized fluid pushes a piston against them. This locks certain gears together and transfers power through the transmission. When the pressure drops, the plates separate and allow the next set of gears to take over.

Bands serve a similar purpose but act like internal brakes. They wrap around rotating drums inside the transmission, tightening to hold parts still when needed. By applying or releasing these bands, the transmission can change gear ratios smoothly and efficiently.

Together, clutch packs and bands are what make an automatic transmission feel effortless. They rely on precise hydraulic pressure and clean automatic transmission fluid (ATF) to keep everything synchronized and responsive.

The Role of the Torque Converter Clutch (TCC)

The torque converter clutch, or TCC, is a special component that improves efficiency in automatic transmissions. It’s located inside the torque converter, which connects the engine to the transmission and uses fluid to transfer power.

At higher speeds, the TCC engages to create a direct mechanical connection between the engine and transmission. This eliminates the small amount of slip that normally occurs in the torque converter, improving fuel economy and reducing heat buildup.

Because it works constantly under changing load conditions, the TCC is often one of the first clutch components to show signs of trouble. When it starts to fail, drivers may notice shuddering at highway speeds, fluctuating RPMs, or a feeling that the transmission can’t decide which gear to stay in.

The Planetary Gear Set Connection

At the heart of every automatic transmission is the planetary gear set, a compact system of gears that creates all the different gear ratios your car needs. The clutch packs and bands control which parts of this gear set are held still and which are allowed to spin.

The gear set includes three main parts: the sun gear at the center, planet gears that orbit around it, and the ring gear on the outside. By locking or releasing these parts in different combinations, the transmission can multiply torque, reverse direction, or send power straight through for cruising speeds.

When viewed in a transmission clutch system, you’d see how applying specific clutch packs and bands redirects the power flow through the planetary gears to produce smooth, automatic shifts.

Signs of a Failing Automatic Transmission Clutch

Automatic transmission clutches are built to last, but wear and heat eventually take their toll. When the internal clutch packs or torque converter clutch begin to fail, your car will usually warn you with a few telltale signs. Paying attention early can help you catch a problem before it turns into a full transmission rebuild.

Slipping or Hesitation During Shifts

Symptom: The engine revs increase, but the vehicle struggles to accelerate or feels like it’s “hunting” for the right gear.

Cause: Worn clutch plates or low transmission fluid pressure prevent the clutch packs from locking properly.

Harsh Engagement or Shuddering

Symptom: The transmission engages suddenly or the car shakes during gear changes.

Cause: A sticking piston, contaminated fluid, or a failing torque converter clutch can disrupt smooth engagement.

Burnt Smell (Overheating Friction Material)

Symptom: A strong, burnt odor from the transmission area or dark, discolored ATF on the dipstick.

Cause: Overheated friction material inside the clutch packs due to slipping, heavy towing, or neglected fluid changes.

Even small clutch issues can create chain reactions that damage seals, bearings, and gears. If you notice these symptoms, it’s best to schedule a diagnosis before the problem spreads.

Diagnosis and Next Steps for Clutch Failure

If you’re dealing with transmission issues, pinpointing the exact cause is key. Automatic transmissions are complex systems where electronic, hydraulic, and mechanical components all work together. What feels like a clutch failure could actually be a fluid, sensor, or control problem. A proper diagnosis can save time, money, and unnecessary repairs.

The Repair Process

When a clutch pack fails, the transmission usually needs to be disassembled and rebuilt or replaced. This is a major job that involves removing the transmission from the vehicle and replacing worn friction plates, seals, and sometimes the torque converter itself. Before assuming mechanical failure, a technician will check for transmission control module (TCM) errors or hydraulic pressure issues that can mimic clutch problems.

Preventive Maintenance: The Role of ATF in Extending Clutch Life

Transmission fluid isn’t just lubrication, it’s what creates the pressure that engages the clutch packs. Old or burnt fluid loses viscosity, reducing hydraulic pressure and allowing the clutches to slip. Regular fluid changes are one of the easiest ways to extend clutch life and prevent overheating.

Don’t Wait: The Cost of Continued Driving

Driving with a slipping clutch can quickly lead to more severe transmission damage. The excess heat can warp internal components, damage seals, and contaminate fluid throughout the system. If you suspect clutch trouble, it’s best to act early to prevent a full transmission failure.

If your vehicle is showing any of these signs, check out FCC’s range of durable clutch systems and components built for long-lasting performance and reliability.

FAQs About Automatic Transmission Clutches

Yes. Automatic transmissions use multiple internal clutch packs inside the transmission housing to engage and disengage gears. Unlike a manual system, these clutches are controlled by hydraulic pressure and electronic timing rather than a pedal.

It transfers engine power to the transmission’s gear sets and controls when those gears engage. This allows the car to shift smoothly without driver input.

With proper maintenance and clean fluid, most clutch packs last between 80,000 and 150,000 miles. Aggressive driving, towing, or neglecting fluid changes can shorten that lifespan.

CVTs operate with belt-and-pulley systems instead of traditional gear sets. Some designs include a start clutch, but they function differently than the clutch packs found in standard automatics.

Common symptoms include slipping gears, delayed shifting, a burnt smell from the transmission, or strange noises during acceleration.

The cost varies widely depending on vehicle type and transmission design. On average, professional replacement can range from $1,500 to $3,500, since the repair usually requires removing and rebuilding the transmission.

A dual-clutch transmission (DCT) uses two separate clutches to control odd and even gears. This allows for quicker, smoother shifts and improved efficiency, which is why DCTs are common in high-performance vehicles.

Change your transmission fluid regularly, avoid unnecessary towing or aggressive driving, and keep your cooling system in good condition. Clean fluid and proper cooling are the two biggest factors in clutch longevity.

They’re usually made from composite materials such as Kevlar, carbon fiber, or paper-based compounds designed to handle high heat and friction.

Yes. Many modern vehicles use software updates to adjust clutch timing, engagement pressure, and shift mapping, which can improve performance and extend clutch life.

Yes, in a way. The torque converter works alongside the clutch packs to transfer power smoothly. You can think of it as the fluid link between the engine and transmission.