Automatic Transmission

(AT) four-wheel clutch for automatic transmission

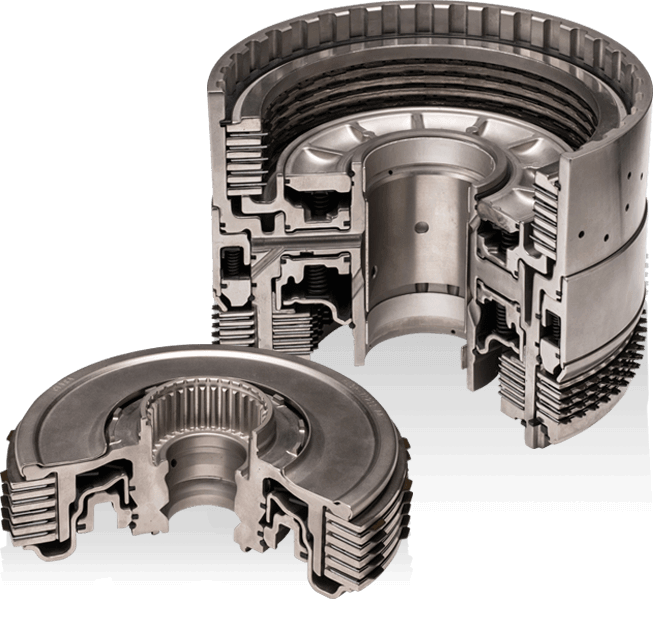

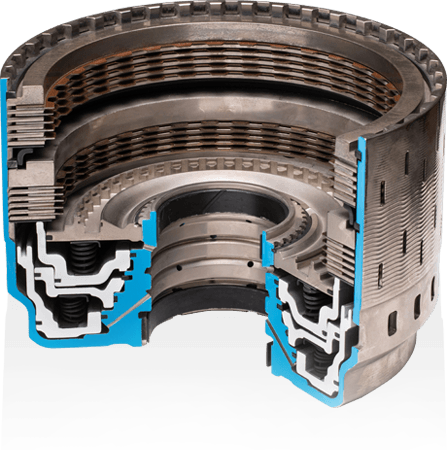

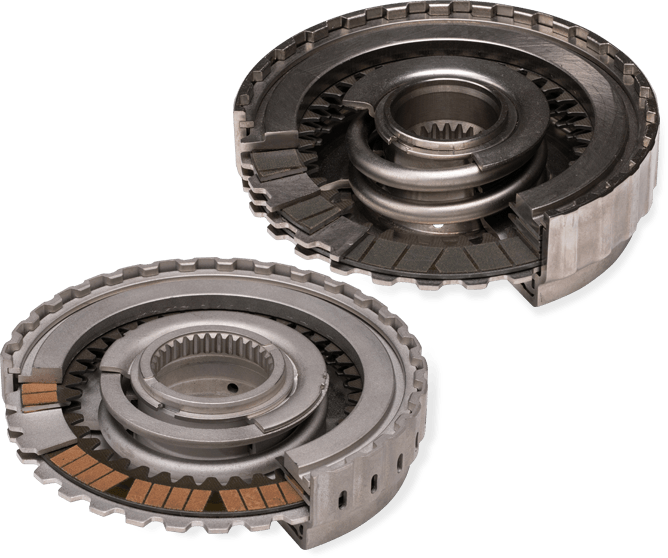

Clutch for 10-speed FR transmission

The triple clutch and single clutch, which integrate three clutches, actively adopt aluminum materials for their constituent parts, realizing a significant weight reduction.

As a manufacturer making clutches from start to finish—from research and development of Joining Technology to their final assembly, F.C.C. has built a global production system of 13 overseas facilities in 9 countries complementing our established bases in Japan.

F.C.C.’s clutches see wide use in motorcycles built by Japan’s leading manufacturers, including Honda, Suzuki, Yamaha, and Kawasaki, and in rival bikes from well-known overseas manufacturers. We are proud that our products rank among the top internationally acclaimed clutches. In automobiles, almost all Honda cars with automatic transmissions shift their gears with the help of F.C.C. clutches.

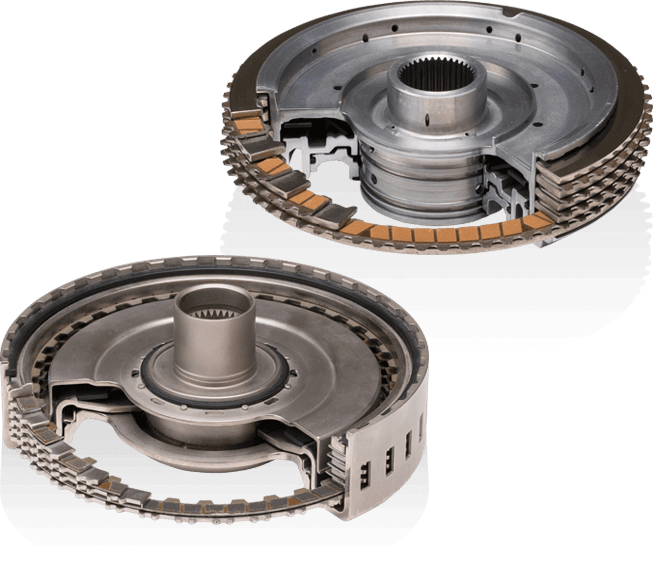

Clutch for FF 9-speed transmission

The adoption of a clutch disc that achieves both low drag torque and heat resistance contributes to improved fuel efficiency and a more compact transmission.

Pursuit of a single field allows the venturer to reach ground where others fail to follow. F.C.C. has dedicated some 70 years to a single functional part, “the clutch,” to become one of the few leading experts in this field. We are now taking our collective strength—forged through our creative ideas, distinguished technology, unparalleled production equipment, and uncompromising quality control—from Japan to the world, as we scale up the making of cutting-edge products to global level. F.C.C. keeps a close eye on the course of motorization in all of the world and pioneers new frontiers in bringing to the world the unseen and the unheard-of. The quest to make the ultimate product moves on at F.C.C., a company of which there is only one.

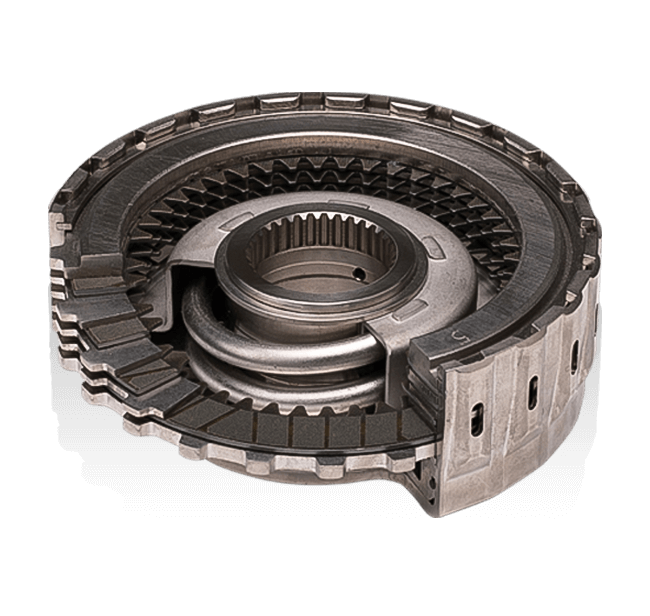

Clutch for FF 8-speed transmission

By adopting the FAD manufacturing method, we have realized a clutch housing with high tooth profile precision on both the inside and outside.

As a manufacturer making clutches from start to finish—from research and development of Joining Technology to their final assembly, F.C.C. has built a global production system of 13 overseas facilities in 9 countries complementing our established bases in Japan.

F.C.C.’s clutches see wide use in motorcycles built by Japan’s leading manufacturers, including Honda, Suzuki, Yamaha, and Kawasaki, and in rival bikes from well-known overseas manufacturers. We are proud that our products rank among the top internationally acclaimed clutches. In automobiles, almost all Honda cars with automatic transmissions shift their gears with the help of F.C.C. clutches.

Clutch for FR 6-speed transmission

A space-saving high-capacity clutch with a double structure equipped with two clutches. Adopted housing by flow forming manufacturing method and aluminum die-cast piston.

Pursuit of a single field allows the venturer to reach ground where others fail to follow. F.C.C. has dedicated some 70 years to a single functional part, “the clutch,” to become one of the few leading experts in this field. We are now taking our collective strength—forged through our creative ideas, distinguished technology, unparalleled production equipment, and uncompromising quality control—from Japan to the world, as we scale up the making of cutting-edge products to global level. F.C.C. keeps a close eye on the course of motorization in all of the world and pioneers new frontiers in bringing to the world the unseen and the unheard-of. The quest to make the ultimate product moves on at F.C.C., a company of which there is only one.

HEV

Four-wheel clutch for HEV

Overdrive clutch for HEV

A small compact clutch that reduces drag torque with a clutch disc that uses the FAS manufacturing method.

As a manufacturer making clutches from start to finish—from research and development of Joining Technology to their final assembly, F.C.C. has built a global production system of 13 overseas facilities in 9 countries complementing our established bases in Japan.

F.C.C.’s clutches see wide use in motorcycles built by Japan’s leading manufacturers, including Honda, Suzuki, Yamaha, and Kawasaki, and in rival bikes from well-known overseas manufacturers. We are proud that our products rank among the top internationally acclaimed clutches. In automobiles, almost all Honda cars with automatic transmissions shift their gears with the help of F.C.C. clutches.

Clutch for twin motor drive unit

High-capacity friction material and low drag torque disk by FAS manufacturing method are adopted. Contributes to improved fuel efficiency during engine running.

Pursuit of a single field allows the venturer to reach ground where others fail to follow. F.C.C. has dedicated some 70 years to a single functional part, “the clutch,” to become one of the few leading experts in this field. We are now taking our collective strength—forged through our creative ideas, distinguished technology, unparalleled production equipment, and uncompromising quality control—from Japan to the world, as we scale up the making of cutting-edge products to global level. F.C.C. keeps a close eye on the course of motorization in all of the world and pioneers new frontiers in bringing to the world the unseen and the unheard-of. The quest to make the ultimate product moves on at F.C.C., a company of which there is only one.

CVT

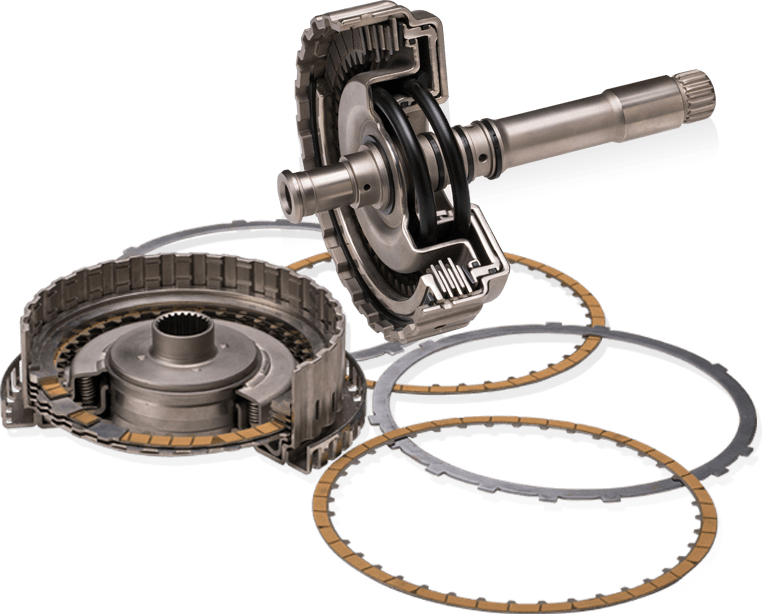

Four-wheel clutch for CVT

Forward clutch/ reverse brake disc

A shaft-integrated clutch that uses a high-μ friction material and achieves compactness.

Forward clutch: Optimization of friction material and tuning of responsiveness by seal material realizes shift select performance without changing vehicle control.

Clutch for reverse brake: Drag torque is reduced by optimizing the friction material groove shape. Contributes to improved fuel efficiency during forward driving.

As a manufacturer making clutches from start to finish—from research and development of Joining Technology to their final assembly, F.C.C. has built a global production system of 13 overseas facilities in 9 countries complementing our established bases in Japan.

F.C.C.’s clutches see wide use in motorcycles built by Japan’s leading manufacturers, including Honda, Suzuki, Yamaha, and Kawasaki, and in rival bikes from well-known overseas manufacturers. We are proud that our products rank among the top internationally acclaimed clutches. In automobiles, almost all Honda cars with automatic transmissions shift their gears with the help of F.C.C. clutches.

Forward clutch/ reverse clutch for mini vehicles

Considering the use in mini vehicles, this clutch uses high-strength steel plate single-draw clutch guides and high-durability friction materials to improve durability and reduce costs.

Pursuit of a single field allows the venturer to reach ground where others fail to follow. F.C.C. has dedicated some 70 years to a single functional part, “the clutch,” to become one of the few leading experts in this field. We are now taking our collective strength—forged through our creative ideas, distinguished technology, unparalleled production equipment, and uncompromising quality control—from Japan to the world, as we scale up the making of cutting-edge products to global level. F.C.C. keeps a close eye on the course of motorization in all of the world and pioneers new frontiers in bringing to the world the unseen and the unheard-of. The quest to make the ultimate product moves on at F.C.C., a company of which there is only one.

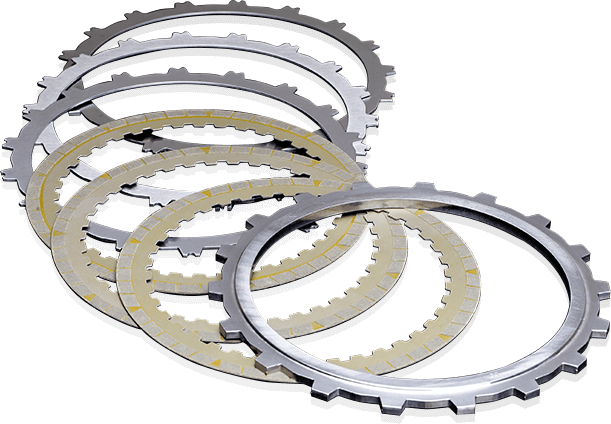

Various wet disks

FSD: Segment groove shape can be selected according to required performance.

FAS: A manufacturing method that enables drag torque reduction and yield improvement

As a manufacturer making clutches from start to finish—from research and development of Joining Technology to their final assembly, F.C.C. has built a global production system of 13 overseas facilities in 9 countries complementing our established bases in Japan.

F.C.C.’s clutches see wide use in motorcycles built by Japan’s leading manufacturers, including Honda, Suzuki, Yamaha, and Kawasaki, and in rival bikes from well-known overseas manufacturers. We are proud that our products rank among the top internationally acclaimed clutches. In automobiles, almost all Honda cars with automatic transmissions shift their gears with the help of F.C.C. clutches.

Lock-up Clutch

lockup clutch

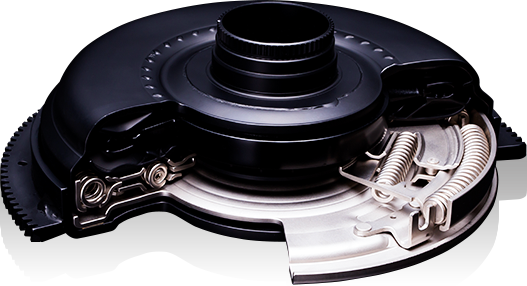

Multi-plate lockup clutch

By adopting a damper with a low spring constant and a multi-plate clutch, the range of lockup applications has been greatly expanded, greatly contributing to improved fuel efficiency.

As a manufacturer making clutches from start to finish—from research and development of Joining Technology to their final assembly, F.C.C. has built a global production system of 13 overseas facilities in 9 countries complementing our established bases in Japan.

F.C.C.’s clutches see wide use in motorcycles built by Japan’s leading manufacturers, including Honda, Suzuki, Yamaha, and Kawasaki, and in rival bikes from well-known overseas manufacturers. We are proud that our products rank among the top internationally acclaimed clutches. In automobiles, almost all Honda cars with automatic transmissions shift their gears with the help of F.C.C. clutches.

Twin damper for lockup clutch

The lower spring constant of the damper expands the lock-up engagement range, contributing to improved fuel efficiency.

Pursuit of a single field allows the venturer to reach ground where others fail to follow. F.C.C. has dedicated some 70 years to a single functional part, “the clutch,” to become one of the few leading experts in this field. We are now taking our collective strength—forged through our creative ideas, distinguished technology, unparalleled production equipment, and uncompromising quality control—from Japan to the world, as we scale up the making of cutting-edge products to global level. F.C.C. keeps a close eye on the course of motorization in all of the world and pioneers new frontiers in bringing to the world the unseen and the unheard-of. The quest to make the ultimate product moves on at F.C.C., a company of which there is only one.

Single plate lockup clutch

Adopting an arc type long torsion spring and tightening it from the low speed range achieves a significant improvement in fuel efficiency.

Two straight damper springs are arranged in series to reduce the spring constant and dynamic hysteresis, greatly improving damping performance and contributing to improved fuel efficiency

As a manufacturer making clutches from start to finish—from research and development of Joining Technology to their final assembly, F.C.C. has built a global production system of 13 overseas facilities in 9 countries complementing our established bases in Japan.

F.C.C.’s clutches see wide use in motorcycles built by Japan’s leading manufacturers, including Honda, Suzuki, Yamaha, and Kawasaki, and in rival bikes from well-known overseas manufacturers. We are proud that our products rank among the top internationally acclaimed clutches. In automobiles, almost all Honda cars with automatic transmissions shift their gears with the help of F.C.C. clutches.

manual transmission

Four-wheel clutch for manual transmission

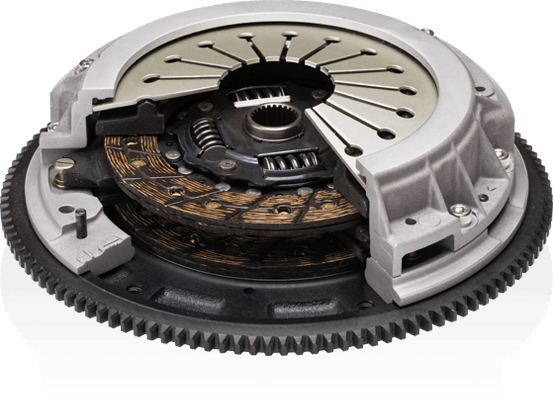

Dry single plate clutch

General clutch used from small to large vehicles.

As a manufacturer making clutches from start to finish—from research and development of Joining Technology to their final assembly, F.C.C. has built a global production system of 13 overseas facilities in 9 countries complementing our established bases in Japan.

F.C.C.’s clutches see wide use in motorcycles built by Japan’s leading manufacturers, including Honda, Suzuki, Yamaha, and Kawasaki, and in rival bikes from well-known overseas manufacturers. We are proud that our products rank among the top internationally acclaimed clutches. In automobiles, almost all Honda cars with automatic transmissions shift their gears with the help of F.C.C. clutches.

dry twin disc clutch

A pressure disk friction follow-up mechanism is adopted for high rotation and high output, and the life of the clutch is greatly improved.

Pursuit of a single field allows the venturer to reach ground where others fail to follow. F.C.C. has dedicated some 70 years to a single functional part, “the clutch,” to become one of the few leading experts in this field. We are now taking our collective strength—forged through our creative ideas, distinguished technology, unparalleled production equipment, and uncompromising quality control—from Japan to the world, as we scale up the making of cutting-edge products to global level. F.C.C. keeps a close eye on the course of motorization in all of the world and pioneers new frontiers in bringing to the world the unseen and the unheard-of. The quest to make the ultimate product moves on at F.C.C., a company of which there is only one.