Papermaking and New Materials Technology

Highly functional materials made from paper.

ABOUT OUR

TECHNOLOGY

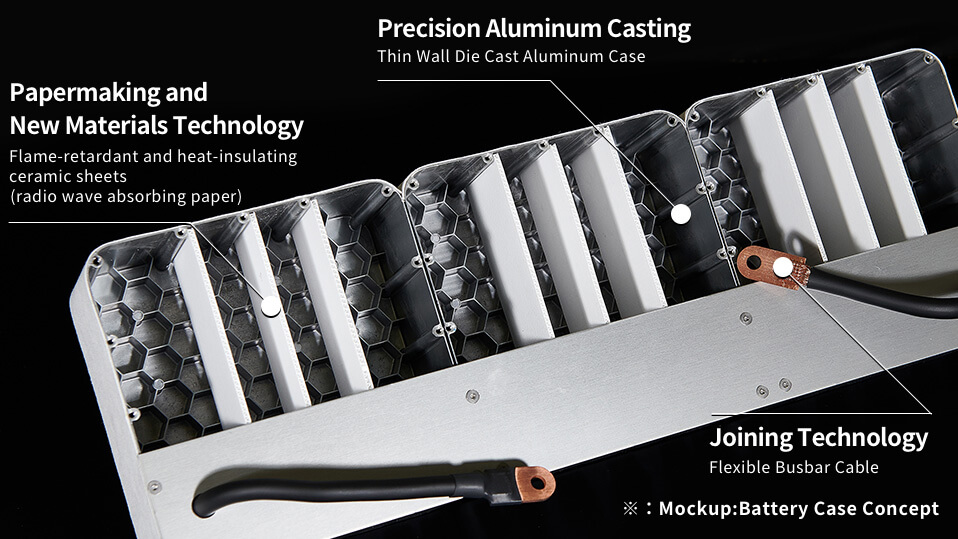

Utilizing FCC’s unique papermaking technology cultivated through the manufacturing of highly durable and highly heat-resistant friction materials, we provide highly functional paper substrates applicable to various products with raw material blending, structure control, and shape control technologies suitable to customer needs, contributing to higher functionality, lighter weight, and cost reduction of products.

Because FCC is a multidisciplinary manufacturer, we are able to handle the processes of folding, bonding, grooving, and forming into universal shapes in addition to paper processing.

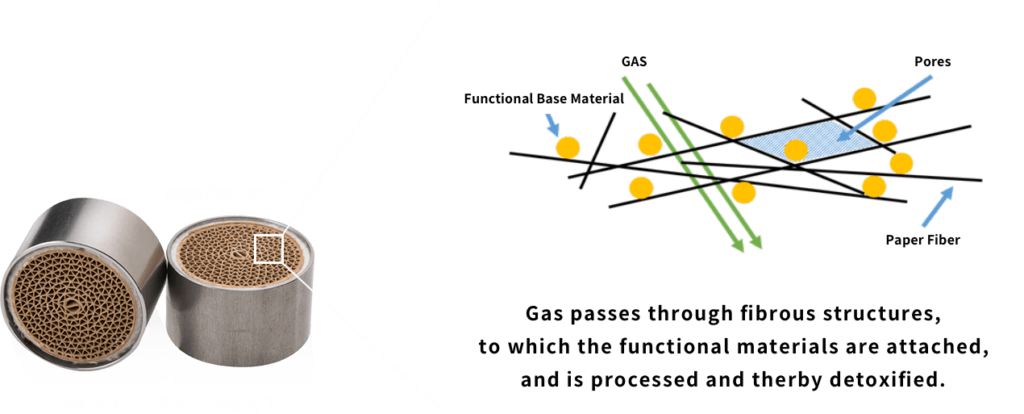

The unique and porous structure of paper is highly applicable at a high level to various applications, such as heat insulation, insulation, radio wave absorption, filtration, and catalysts; in terms of thermal management, it can be applied to the development and manufacture of EVs and related products as well.

Using the friction material manufacturing technologies, we develop new materials in-house that create value in a variety of fields and manufacture them in small lots.

What can Papermaking and New Materials Technology Do?

Small cutting tool allowing deep groove machining

Custom Fiber Spacing Technology

- Customizable spacing for application of functional material

- Convert difficult-to-handle materials into easy-to-use forms (good handling and processing)

- Using Paper as temporary molds (later applying functional material)

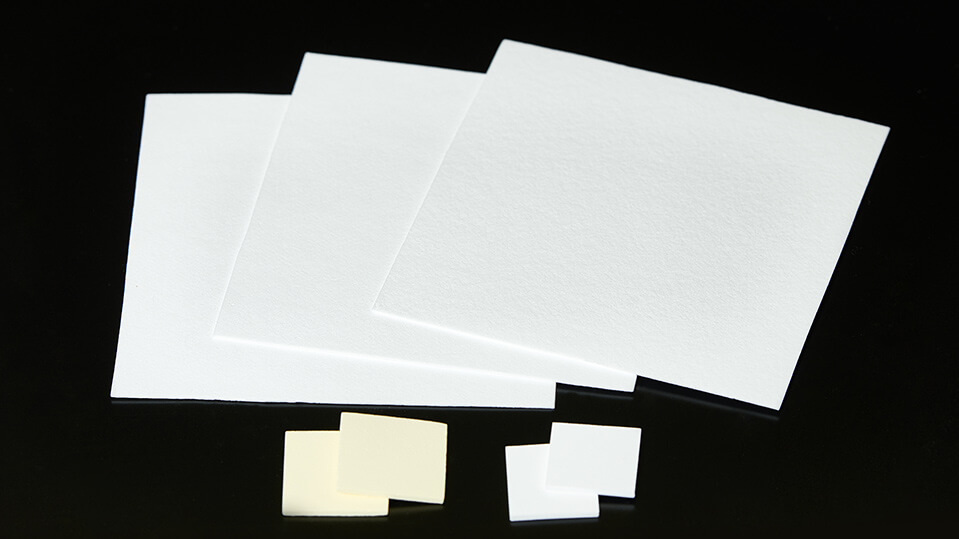

Total Control Paper Structure

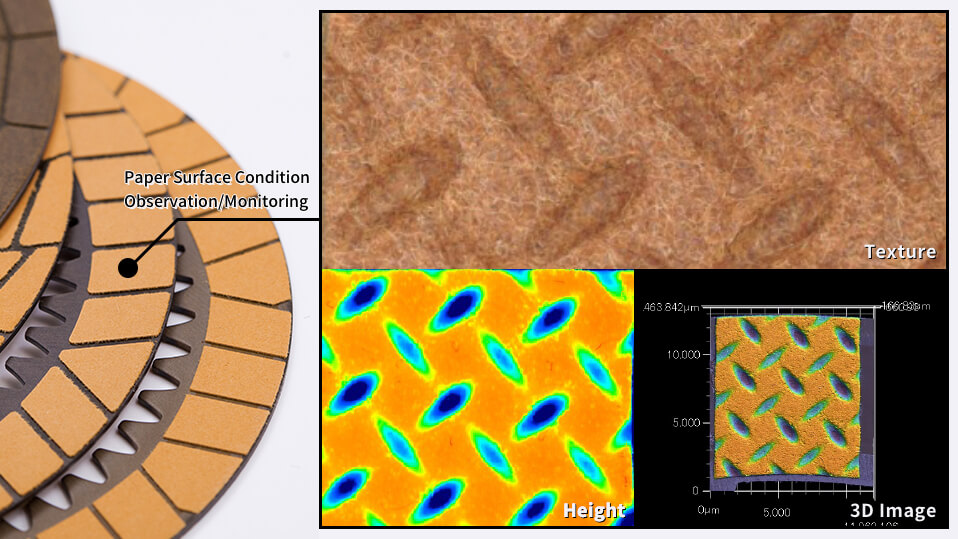

Paper structure is controlled in the papermaking process. Various shapes are provided in response to the applications such as thickness, density, surface structure (grooves, unevenness), and internal structure control (porosity).

Products with High Precision Control of Paper Structure

- Creating specific functionalities through control of paper surface conditions

- Porous structure control opens the door for expansion into filter applications

- Thickness control, capable of handling paper thicker than 1 mm

OUR ADVANTAGES

Formula designs tailored to the application

Adjustable Paper Structure and Surface Condition control

Develop/Manufacture Prototypes Well-Organized Production Environment

Analysis and Evaluation

Combination of Casting Technology and Joining Technology Challenges in Uncharted Fields

PRODUCT REALIZATION

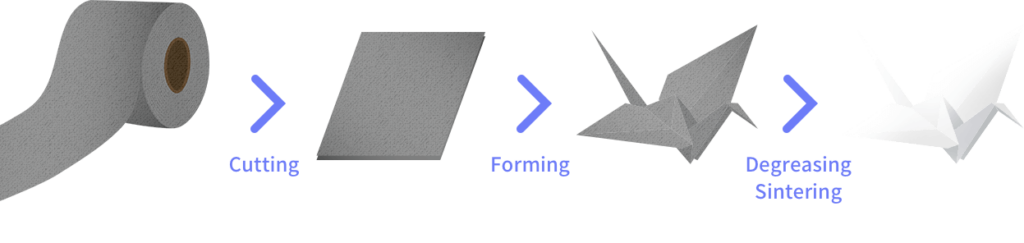

Paper Ceramics Technology

Forming Ceramics into Various Shapes

Forming in the Paper state provides the flexibility and ease of processing.

Ceramics with complex shapes are achieved at low cost by sintering through heat treatment after forming.

Material Flexibility

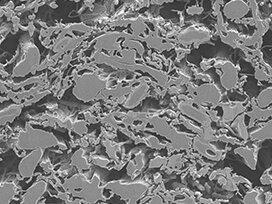

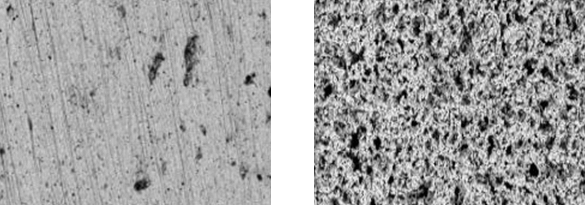

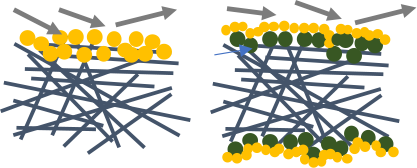

Porosity Control by Organic Content

The paper constituent contained in paper ceramics is burned off when heated.

The porosity is controllable by manipulating the size and number of pores created with the organic material is burned away.

Realization of Thin-Wall Ceramics

Formed from thin paper, thin sheet shapes are easily formed.

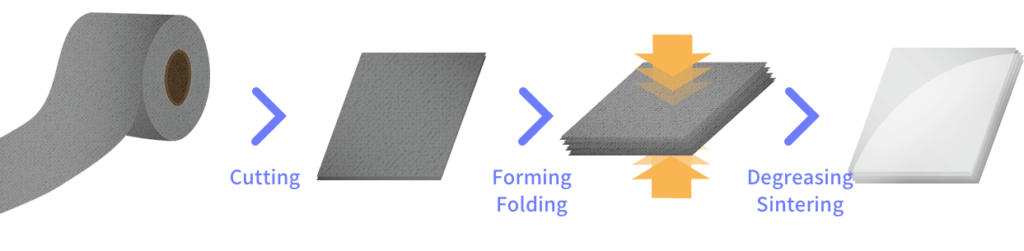

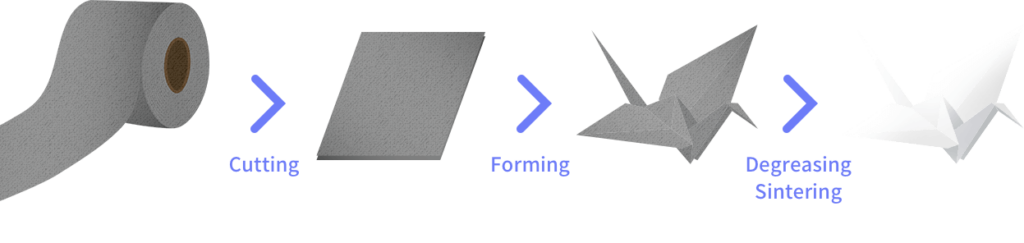

Manufacturing Process

Processing of Ceramics by Paper Folding

Formation of Processed Ceramics by Paper Lamination

Lamination Forming Technology

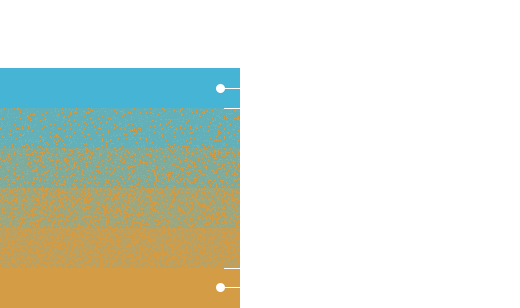

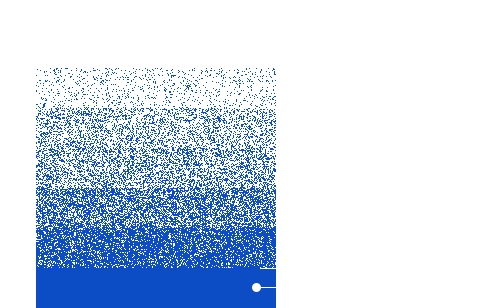

Multi-Layer Material

Ceramic work pieces having customizable geometry structure is formed by laminating ceramic soaked paper with different porosities and material compositions.

Image of Composition Gradient Material

Image of controllable Porosity amounts within customizable geometries

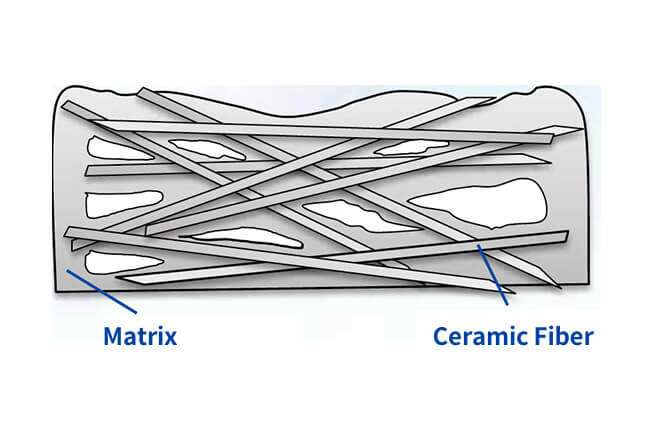

Fiber Composite Materials

Paper structure + ceramic fibers create a light weight, high heat resistance and high elasticity.

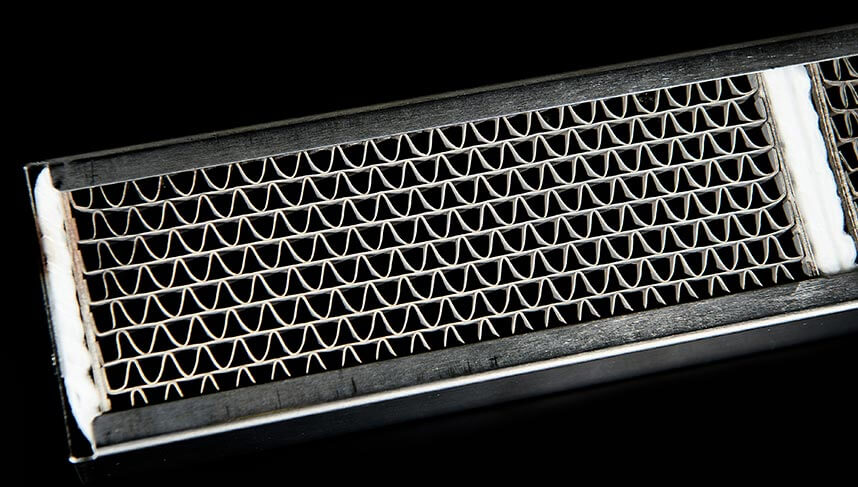

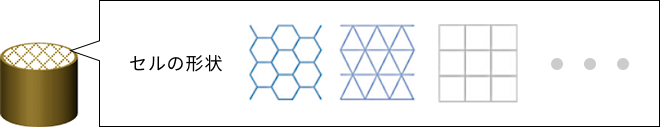

Catalytic converter for general-purpose engines (honeycomb)

Catalytic unit for wood stove

VISION

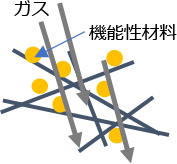

Research on Catalytic Reaction Control Technology

Aim of the Study

Technology Overview

Step 01

Step 02

Step 03

How does it work?

Research Direction

Raw Materials Research

Research on paper structure and conditions and manufacturing technology

【Rectangular Solid】

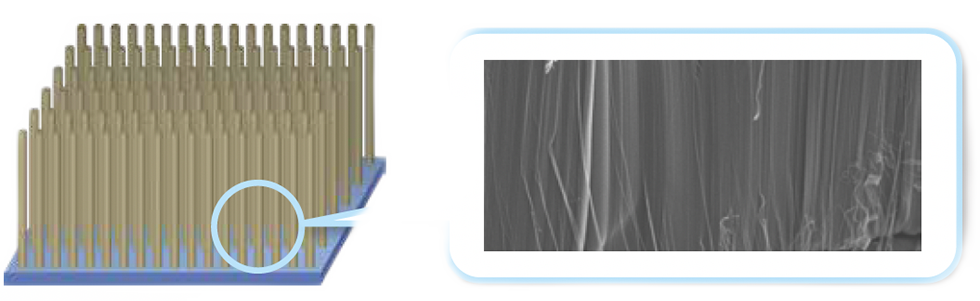

Utilization of Nanomaterials:

Carbon Nanotubes

Nano material application :

carbon nanotubes

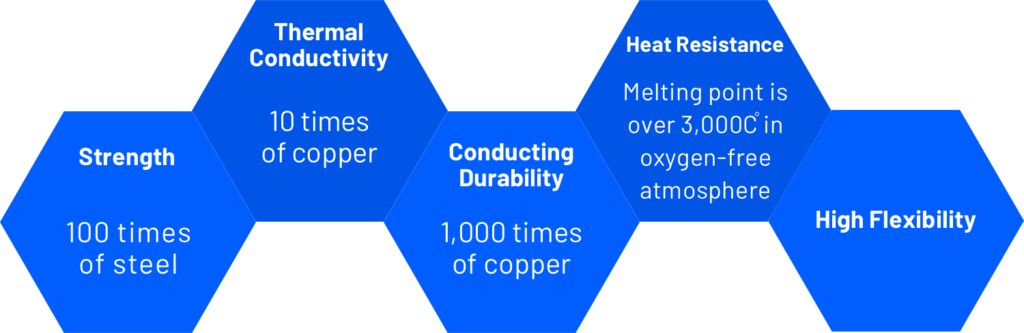

Based on our research of core material selection technologies, we focused on the high-performance material, carbon nanotube.research of core material selection technologies, we focused on the high-performance material, carbon nanotube.

We have launched a joint business with [Kanematsu Corporation], which is committed to “Creating the value demanded by society,” and [CarbonFly Inc.], which specializes in carbon nanotubes.

Features of CarbonFly, Inc.

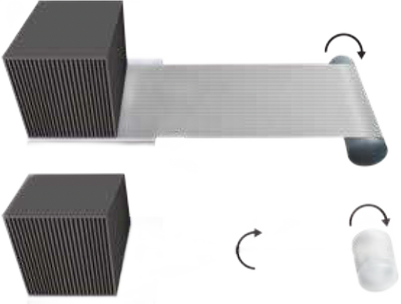

Features of carbon nanotube substrate [CNT]

Product Deployment Examples

LiB Electrode

Structural components, Orthopedic, and aerospace components

Sports/Leisure and Health Care

EXHIBITION PRODUCTS

A technology that has a potential to play an active role in a variety of fields, such as next-generation automobiles, medical care, energy, information and telecommunications, and agriculture.

We will contribute to solving the challenges in the world.

MEDICAL

Social Issues to Solve

Technology Solution

Artificial bone / Lost bone regeneration

High reproducibility achieved with highly flexible generation technology.

ENERGY

Social Issues to Solve

Technology Solution

Providing highly efficient / lightweight structural components for transportation equipment

Reduction of losses in heat treatment process by manufacturing lightweight furnace materials: Realization of lightweight / heat resistance

Manufacturing of gas turbines using ceramic composite materials: Ultra-high heat resistance / high durability.

IT

Social Issues to Solve

Smaller, Lighter, and Higher Power devices.

Technology Solution

Manufacturing heat sinks/sheets

Controlling the heat in electronic devices: High thermal conductivity.

FOOD TECH.

Social Issues to Solve

Global food shortages, water insecurity, declining agricultural workforce.

Technology Solution

Manufacturing of antimicrobial sheets

Food preservation, antibacterial sheet

Water Treatment Membrane

Water quality improvement: Permeability control.