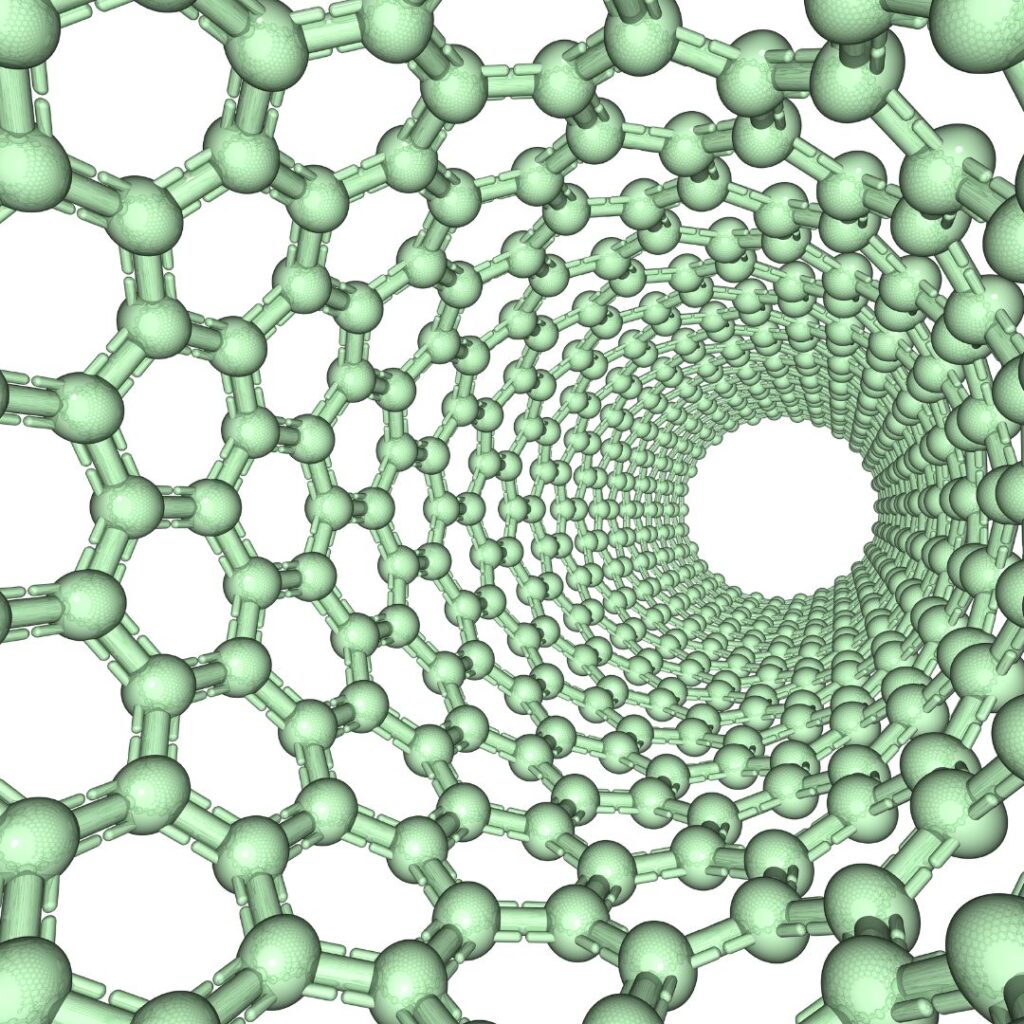

Carbon nanotubes (CNTs) are a fascinating class of material with the potential to revolutionize many fields. Carbon nanotubes are cylindrical structures made up of carbon atoms arranged in a hexagonal lattice. They can be thought of as rolled-up sheets of graphene with tubes of different diameters and lengths, which possess remarkable mechanical, electrical, and thermal properties.

Carbon nanotubes can be single-walled (consisting of a single layer of graphene) or multi-walled (consisting of multiple concentric layers of graphene). Their unique structure gives rise to a variety of applications across various fields such as electronics, materials science, medicine, and energy.

In this article, FCC will delve into what they are, how they came to be discovered, the current carbon nanotube applications, and the research being conducted on the potential carbon nanotube applications.

As pioneers in innovative technology ourselves, we at FCC are always on the lookout for technology that can help us continue to serve our customers diligently with advanced composite clutch products and new technologies.

Learn More About Our Clutch Housing Manufacturing Process Today!

Brief History of Carbon Nanotubes Discovery

The discovery of carbon nanotubes dates back to 1991 when Japanese physicist Sumio Iijima observed carbon fibers while working at NEC Corporation’s Fundamental Research Laboratory. Initially, Iijima was investigating the structure of soot produced by a carbon arc discharge between two graphite electrodes. He used high-resolution transmission electron microscopy (HRTEM) to examine the material and discovered the presence of cylindrical structures made of carbon atoms.

These structures were unlike anything previously observed, possessing diameters in the nanometer range and lengths up to micrometers. Iijima’s groundbreaking work paved the way for extensive research into the properties and potential carbon nanotube applications, leading to their widespread recognition as one of the most promising nanomaterials.

Types of Carbon Nanotubes

There are two main types of CNTs:

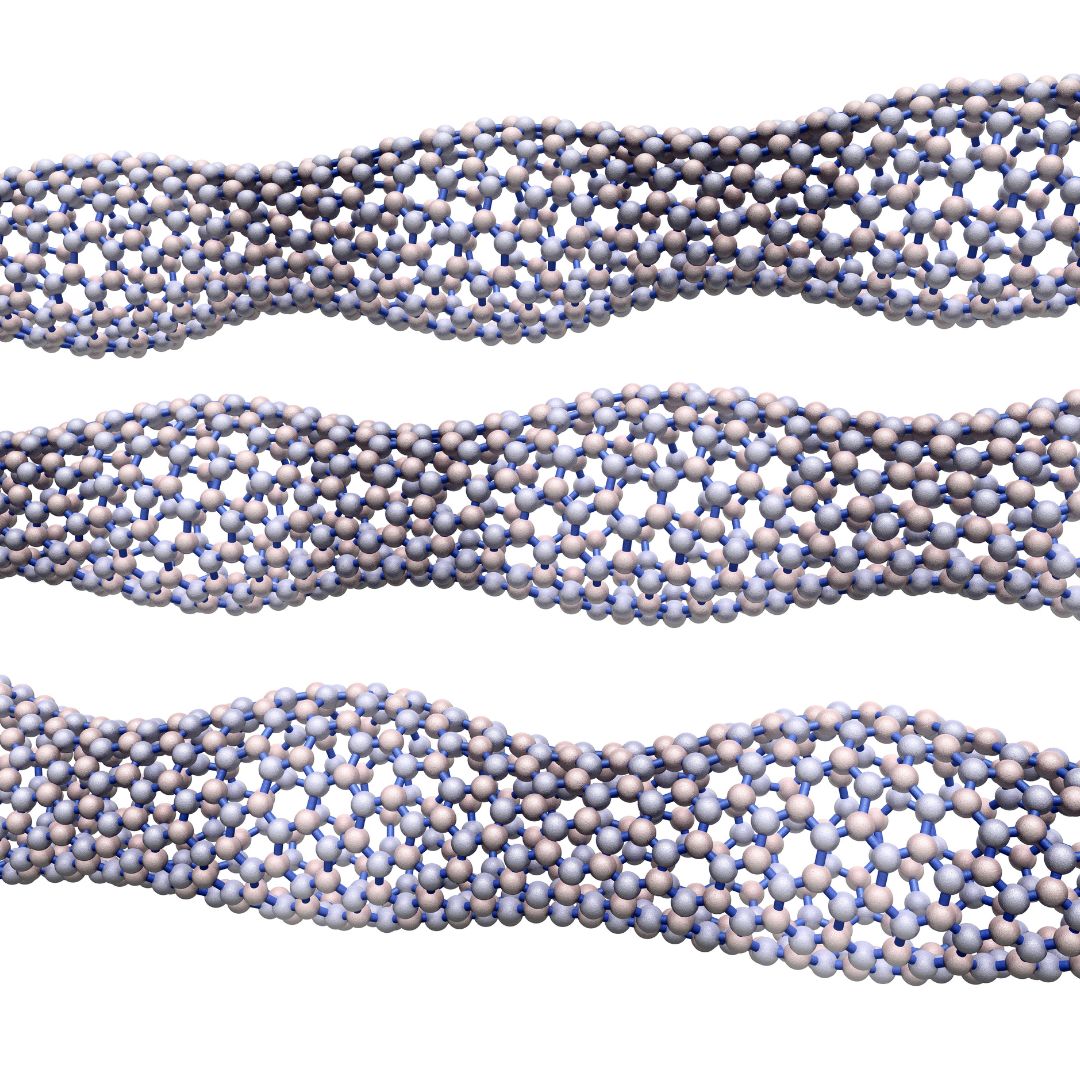

Single-walled Carbon Nanotubes (SWCNTs)

Single-walled carbon nanotubes (SWCNTs) are incredibly thin cylinders made from a single layer of graphene. Their diameters range from 0.5 to 2.0 nanometers but still, they can exhibit exceptional mechanical, electrical, and thermal properties. Single-walled carbon nanotubes can be metallic or semiconducting based on their chirality. At the moment their carbon nanotubes applications can be found in electronics, sensors, nanocomposites, and biomedical devices due to their unique properties.

Multi-walled Carbon Nanotubes (MWCNTs)

As the name suggests, Multi-walled carbon nanotubes (MWCNTs) consist of multiple concentric layers of graphene tubes nested one inside the other, resembling a Russian nesting doll. Their diameters can range from a few nanometers to tens of nanometers. Due to their structure, multi-walled carbon nanotubes exhibit enhanced mechanical strength, improved electrical and thermal conductivity, and chemical stability. Multi-walled carbon nanotube applications can be found in energy storage, reinforcement materials, catalyst supports, and biomedical fields.

Structural Properties

The unique properties of carbon nanotubes (CNTs) stem largely from their remarkable structure. Let’s delve deeper into this.

Nanotube Diameter and Length

The diameter of a carbon nanotube refers to the width of its cylindrical structure. In single-walled carbon nanotubes, the diameter typically ranges from about 0.5 to 2.0 nanometers, and from a few to tens of nanometers in multi-walled carbon nanotubes. The diameter significantly influences the electronic and mechanical properties of carbon nanotubes. For example, smaller-diameter nanotubes tend to exhibit semiconducting behavior, while larger-diameter nanotubes may behave as metallic conductors.

The length of a carbon nanotube on the other hand refers to the extent of its cylindrical structure along the axial direction. Carbon nanotube length varies from nanometers to micrometers. Longer tubes offer flexibility in carbon nanotubes applications like reinforcing composites or making electronic devices. However, achieving uniform lengths of carbon nanotubes remains a challenge in large-scale production.

Chirality and its Influence

Chirality plays a crucial role in carbon nanotubes, defining their electronic properties and impacting their potential applications. Charilty, characterized by two indices, (n, m), describes the nanotube’s structure and determines whether nanotubes exhibit metallic or semiconducting behavior.

Specific chiralities also influence optical properties such as light emission and adsorption. Metallic nanotubes possess high electrical conductivity, ideal for electronics, while semiconducting ones offer tunable bandgaps for applications like transistors and photodetectors. Chirality also affects mechanical properties like tensile strength and flexibility, broadening the scope of potential uses for these structures.

Synthesis Methods

While carbon nanotubes hold immense promise for revolutionizing various fields, harnessing their potential requires efficient and scalable methods for their synthesis.

Chemical Vapor Deposition (CVD)

Chemical vapor deposition (CVD) grows carbon nanotubes from hydrocarbon gases on a catalyst substrate at high temperatures (~600-1000°C). Metals like iron, nickel, or cobalt on substrates like silicon or quartz catalyze the decomposition of gases like methane or ethylene into carbon atoms. The carbon nanotubes are then formed on the catalyst surfaces.

Chemical vapor deposition allows precise control for consistent, high-quality carbon nanotubes but requires careful process management. This can lead to increased production costs due to high temperatures and choice of catalyst and substrate materials.

Arc Discharge

Arc discharge produces carbon nanotubes by passing a high current between graphite electrodes in an inert atmosphere. This intense heat vaporizes the electrodes to form carbon vapor that nucleates carbon nanotubes on the electrode surfaces. These nanotubes are then collected and purified.

While cost-effective, arc discharge yields a mix of multi-walled and single-walled carbon nanotubes. This requires additional purification and highlights the lack of precise control over diameter and chirality.

Laser Ablation

Laser ablation synthesizes carbon nanotubes by irradiating a graphite target with a high-power laser in a reactive gas. This then forms a carbon vapor plume that condenses to form carbon nanotubes. Laser ablation offers a rapid and efficient method for synthesizing carbon nanotubes with high yields and purity. However, it requires costly equipment, and energy, and may generate unwanted by-products and defects.

Mechanical Properties

Carbon nanotubes are renowned for their remarkable mechanical properties, making them some of the strongest and most versatile materials ever discovered.

Strength and Durability

Carbon nanotubes are renowned for their exceptional strength, which comes from the covalent bonds between carbon atoms in their hexagonal lattice structure. With single-walled carbon nanotubes reaching hundreds of gigapascals (GPa) in tensile strength, they are among the strongest materials.

Multi-walled variants exhibit slightly lower tensile strength but can still surpass many other materials. This strength-to-weight ratio makes them valuable reinforcements for composites as they improve their mechanical properties. Their durability can withstand deformation under strain due to the presence of sp² carbon bonds, maintaining their integrity in harsh conditions like high temperatures, corrosive environments, and irradiation.

Flexibility and Elasticity

Despite their immense strength, carbon nanotubes are remarkably flexible due to their cylindrical structure. The ability of carbon bonds to rotate freely, also allows them to bend and twist without breaking. This flexibility makes them ideal for flexible electronics, sensors, and actuators.

Carbon nanotubes are also known to display elastic behavior. They can deform under stress and return to their original shape afterward. This elasticity is attributed to the reversible stretching and bending of carbon bonds within the nanotube structure. Because they have high elastic moduli, carbon nanotubes efficiently store and release mechanical energy, which makes them beneficial for nanoscale springs, shock absorbers, and energy storage devices.

Electrical Properties

One of the most fascinating aspects of carbon nanotubes lies in their remarkable electrical properties. Depending on their structure, carbon nanotubes can exhibit either metallic or semiconducting behavior. This makes them highly versatile for various electronic applications.

Conductivity of Carbon Nanotubes

Certain carbon nanotubes exhibit metallic conductivity, meaning they can efficiently conduct electricity with minimal resistance. These ‘metallic’ carbon nanotubes typically have a symmetric lattice structure and exhibit a linear electronic band structure, allowing for the free movement of electrons along the length of the nanotube.

The conductivity of metallic carbon nanotubes is comparable to that of metals like copper or silver. This makes them suitable for applications in electrical interconnects, nanoelectronics, and transparent conductive films.

Semiconducting Properties

The semiconducting properties of carbon nanotubes are closely related to their chirality, which dictates their electronic band structure. The bandgap of a carbon nanotube can be tuned by selecting nanotubes with specific chiralities. This allows precise control over their electrical properties. By modulating the diameter and chirality of carbon nanotubes, researchers can engineer nanotubes with tailored bandgaps suited for specific electronic applications.

Thermal Applications

Carbon nanotubes (CNTs) are not only electrically versatile but also excel in managing heat. Their exceptional thermal conductivity makes them ideal for various thermal applications.

Heat Dissipation in Electronics

In modern electronics, such as integrated circuits and microprocessors, heat dissipation is a significant challenge. As electronic devices become smaller and more powerful, they generate more heat, leading to an increased risk of overheating and decreased performance and reliability.

Carbon nanotubes offer promising solutions due to their exceptional thermal properties. With high thermal conductivity, they efficiently transport heat away from electronic devices, aiding effective thermal management. Carbon nanotube-based materials, such as thermal interface materials (TIMs) and heat spreaders, have been developed to improve heat dissipation in electronic packaging and cooling systems.

Thermal Conductivity Enhancement

Carbon nanotubes possess exceptionally high thermal conductivity along their axial direction, surpassing that of most conventional materials, including metals like copper and silver. This high thermal conductivity is due to the strong covalent bonds between carbon atoms and the ordered arrangement of atoms in the graphene lattice structure.

By incorporating carbon nanotubes into polymer matrices or composite materials, the thermal conductivity of the resulting composites can be significantly enhanced. Carbon nanotube-based composites have found applications in various thermal management systems, including heat sinks, thermal interface materials, and thermal interface pastes.

Structural Applications

The remarkable strength, stiffness, and lightweight nature of carbon nanotubes make them highly attractive for structural applications. By incorporating carbon nanotubes into composite materials, researchers are paving the way for a new generation of stronger, lighter, and more durable structures.

Reinforcement in Composite Materials

Carbon nanotubes are known for their exceptional mechanical properties, including high tensile strength, stiffness, and flexibility. These physical properties make carbon nanotubes ideal candidates for reinforcing composite materials, where they can enhance the mechanical performance and durability of the composites.

When integrated into polymers, metals, ceramics, or other matrices, nanotubes act as reinforcing agents, improving composite material performance. Their high aspect ratio and surface area enable efficient load transfer and stress distribution especially when in used automotive, aerospace, construction, and sports equipment.

FCC innovations are always looking ahead. We can provide highly functional paper substrates including ceramics, which apply to various products. With raw material blending, structure control, and shape control technologies we use our friction material manufacturing technologies to develop new in-house materials to suit our customer needs.

Learn More About Our Papermaking And New Materials Today!

Aerospace and Structural Engineering

Carbon nanotubes have revolutionized aerospace and structural engineering. Research into their potential and prospective implementation determines that carbon nanotubes offer lightweight yet strong and durable solutions. In structural engineering, carbon nanotube-reinforced materials hold promise for improving fuel efficiency and performance, ensuring durability in aerospace components and structural materials. From spacecraft to buildings, they can bolster strength and resilience, advancing sustainability.

Medical Applications

Carbon nanotubes (CNTs), with their unique properties, are poised to revolutionize the field of medicine. Their potential applications range from targeted drug delivery to advanced imaging techniques.

Drug Delivery Systems

Carbon nanotubes offer versatile platforms for drug delivery systems. Functionalized carbon nanotubes can be designed to selectively bind to target cells or tissues, allowing for precise delivery of therapeutic payloads while minimizing off-target effects. Due to their high surface area and unique nanostructure, carbon nanotubes can protect encapsulated drugs, shielding them from degradation and premature release.

These systems can be engineered to achieve controlled release kinetics, which then allows for sustained drug release over time. This can be achieved by adjusting factors such as nanotube functionalization and response to external stimuli like pH or temperature.

Imaging and Diagnostics

Carbon nanotubes can be functionalized or loaded with imaging agents, such as fluorescent dyes or contrast agents, to enhance their visibility in medical imaging techniques such as fluorescence imaging, magnetic resonance imaging (MRI), and computed tomography (CT) scans. They serve as biosensors for detecting disease markers which then enables early diagnosis and monitoring. They also promise theranostic applications for more precise treatment and monitoring.

Energy Storage

The quest for clean and efficient energy storage solutions for a sustainable future is never-ending. Carbon nanotubes, with their remarkable properties, are emerging as promising candidates for revolutionizing battery and supercapacitor technology.

Supercapacitors

Supercapacitors are energy storage devices known for their ability to store large amounts of energy and release it rapidly. Carbon nanotubes offer significant advantages for enhancing supercapacitor performance in terms of tech, storage, and releasing energy efficiently. Their high surface area amps up capacitance, while superb conductivity enables rapid charge/discharge rates. This then makes them ideal for quick responses to electrical demands. With excellent cycling stability, carbon nanotube-incorporated supercapacitors are perfect for renewable energy and electric vehicles.

Batteries

Batteries are rechargeable electrochemical devices that store energy for longer durations than supercapacitors. Carbon nanotubes can be used as anode materials in lithium-ion batteries and other types of rechargeable batteries. This is due to their high surface area and electrical conductivity which allows them to rapidly diffuse ions and transfer electrons.

Their flexibility and lightweight nature suit wearable applications, promising a new era of portable energy solutions such as wearable electronics, medical devices, and smart textiles.

Environmental Applications

Carbon nanotubes also hold immense promise for tackling environmental challenges. Their unique properties can be harnessed for water purification and air filtration, paving the way for a cleaner and healthier planet.

Water Purification

The global need for clean and accessible water is ever-increasing. Research shows carbon nanotubes present innovative solutions for addressing these concerns due in part to their high surface areas, which enables them to potentially efficiently remove contaminants via adsorption. They can adsorb a wide range of pollutants, including heavy metals, organic compounds, and microbial pathogens, through mechanisms such as physical adsorption, chemical adsorption, and electrostatic interactions.

Carbon nanotube-based absorbents can be regenerated and reused multiple times, making them cost-effective and environmentally sustainable solutions for water treatment.

Air Filtration

Air pollution is a major health concern globally. Carbon nanotubes offer promising possibilities through research into developing next-generation air filtration systems. Carbon nanotubes due to their high surface area and porous structure, can be incorporated into air filtration systems to remove airborne pollutants, such as particulate matter, volatile organic compounds (VOCs), and gases.

Functionalized carbon nanotubes can also exhibit antibacterial properties, making them effective at removing and inhibiting the growth of bacteria and viruses in air filtration applications. This can help prevent the spread of airborne pathogens and reduce the risk of respiratory infections in indoor environments. With low-pressure drop and high airflow, Carbon nanotube-based air filters are energy-efficient and versatile for various applications.

Summary

Carbon nanotubes are versatile nanomaterials with a wide range of applications and potential applications across industries. They offer unique properties such as high strength, conductivity, and biocompatibility.

They are currently driving technological advancements, improving performance and efficiency, and addressing critical challenges in electronics, materials science, energy, healthcare, and environmental sustainability.

Through continued research and development, carbon nanotube-based technologies hold the promise of further innovations and transformative impacts in diverse fields. FCC is invested in enhancing the markets we engage with by consistently delivering innovative products that meet the evolving needs of our customers. Our approach integrates creative ideas and cutting-edge technologies like carbon nanotubes applications, all while prioritizing safety and environmental responsibility.

Learn More About Our Innovative Technology Today!