Joining Technology

ABOUT OUR

TECHNOLOGY

Joining is one of the essential processes to combine two or more members to make products with more sophisticated shapes.

Recently, dissimilar joining, in which materials with different properties are used in the right places for lighter weight and reduced cost, has been attracting more attention.

FCC’s unique joining technology (ring mash joining), which was researched and developed, has made it possible to join dissimilar materials with different melting points, which was previously thought to be impossible.

FCC’s joining technology, which has been cultivated through clutch manufacturing, is evolving daily with our development capability to create unique manufacturing methods and will respond to the needs of the new era.

OUR ADVANTAGES

Selection of Optimal Joining Process to Suit the Material and Needs

Jig Design

CAE Joining Prediction is Under Development

TRY according to Product Needs

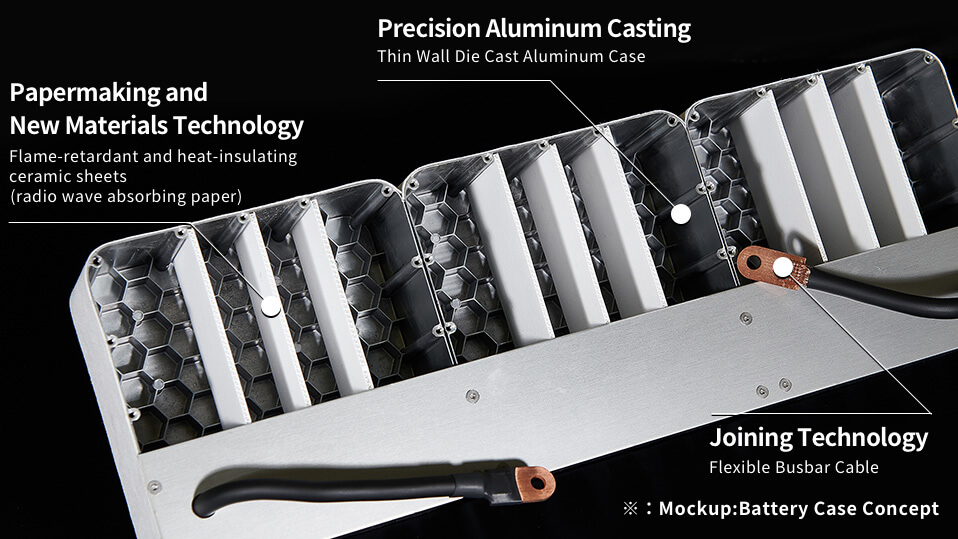

Joining of dissimilar Materials having Different Melting Points by Combining Papermaking and Casting Technologies

MANUFACTURE TECHNOLOGY

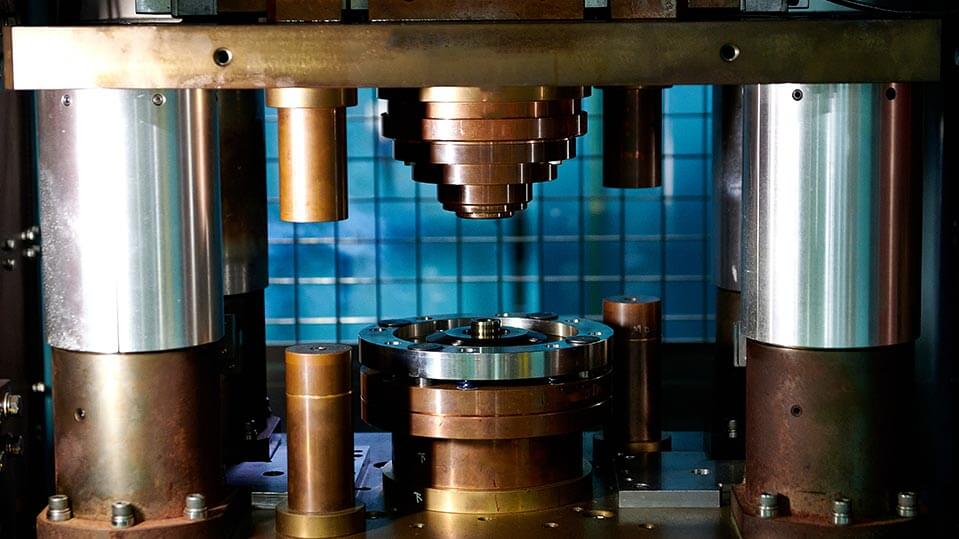

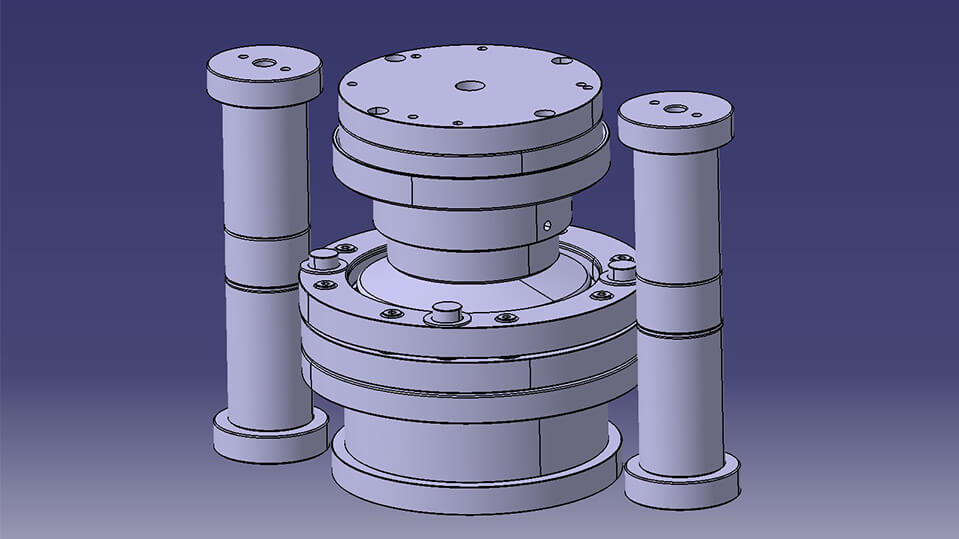

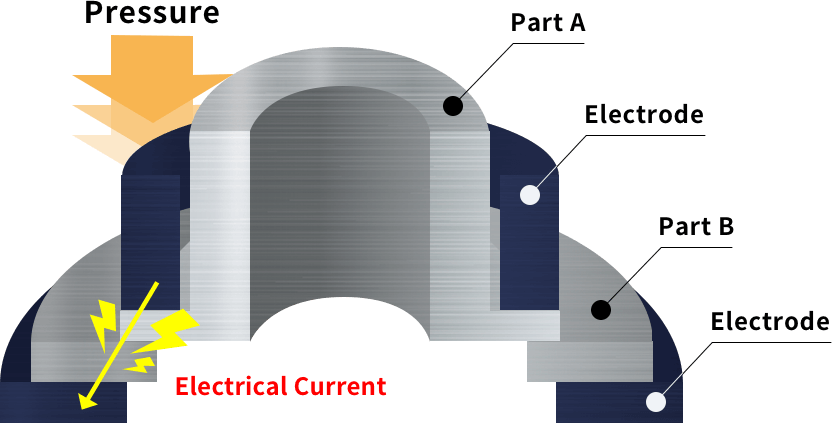

Ring Mash Joining

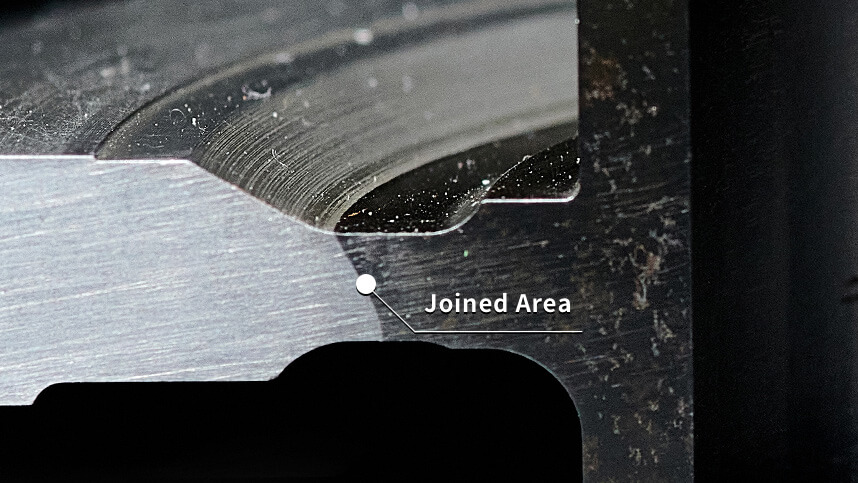

Ring Mash*1 joining, which FCC has independently researched and developed for drive train components, is a joining technology that uses the heat of electrical resistance to soften the joint and pressure weld it, realizing a quick and beautiful finish.

Instead of fusing, the metal is softened and pressure welded while in the solid state. In addition to the joining of dissimilar materials, it also enables the joining of heterogeneous materials, such as steel and aluminum, which is essential for next-generation automobiles that aim to save space and reduce weight.*2

*2. Steel and aluminum heterogeneous joining by Ring Mash joining is a patented technology of FCC.

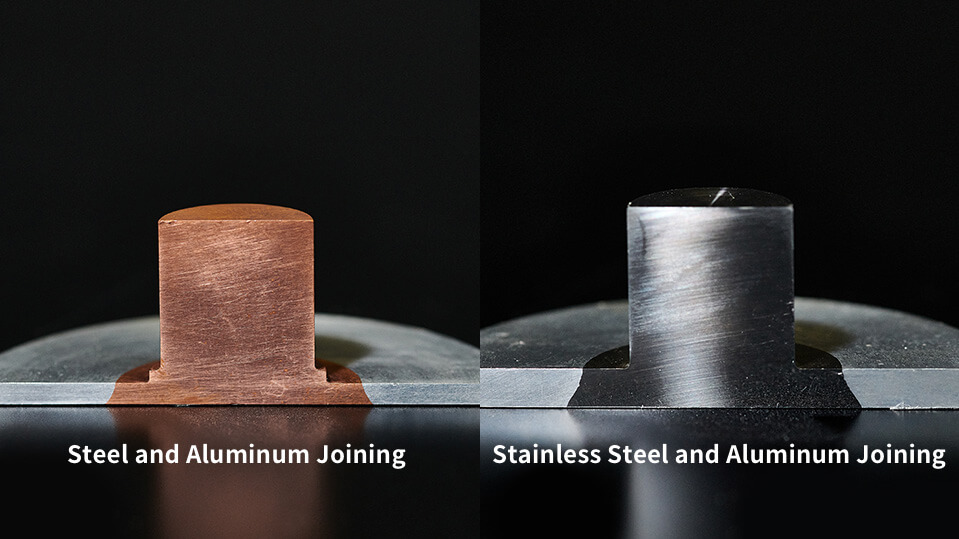

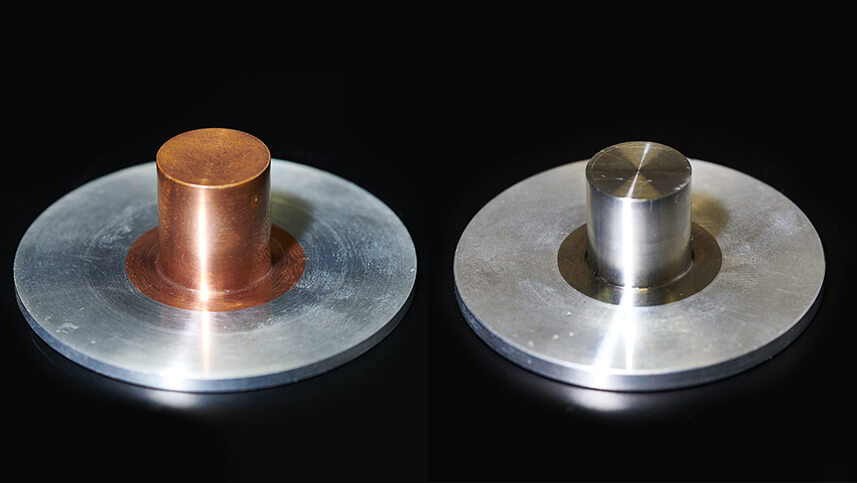

Image of Joining dissimilar Materials

Motorcycle Pulley Parts: Joining steel and aluminum dissimilar materials

Left: dissimilar joining of copper and aluminum

Right: dissimilar joining of stainless steel and aluminum

Features

Shortened Cycle Time, Increased Efficiency

The joining surface is instantly heated and softened by an electric current, and the substrates are joined in less than 0.1 seconds.

The cycle time is drastically reduced compared to conventional methods.

Furthermore, the smoothness of the bonded surfaces eliminates the need for sputtering treatment.

Highly efficient production with minimized processing.

Achieve Lightweight and Cost Reduction by Joining dissimilar Materials

Joining dissimilar materials, such as steel and aluminum and copper and aluminum, promotes reductions in weight and the reduced cost of materials.

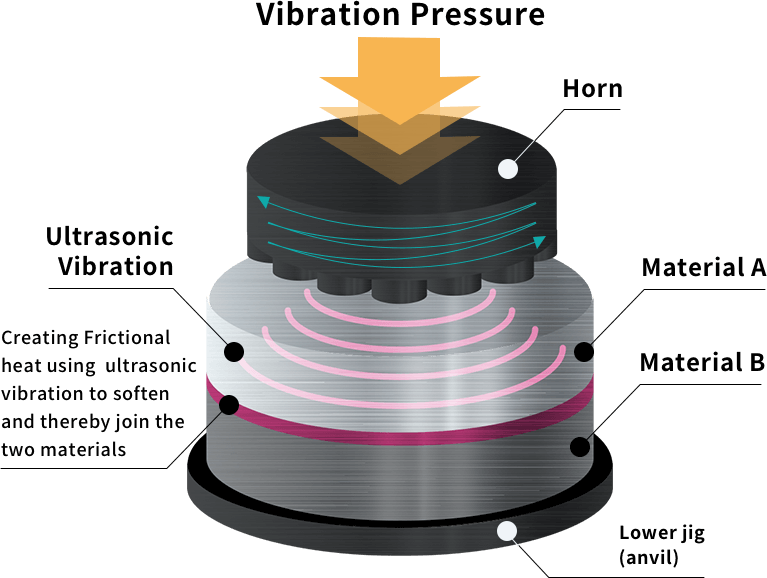

Ultrasonic Joining

Features

Other Technologies Owned

TIG Welding

MIG Welding

Plasma Welding

Less thermal distortion compared to TIG or MIG welding.

Electron Beam Welding

Laser Beam Welding

Spot Welding

Short joining time and low thermal distortion due to heating only at the joining zone.

Comparatively inexpensive equipment cost.

Projection Welding

NEW TECHNOLOGY

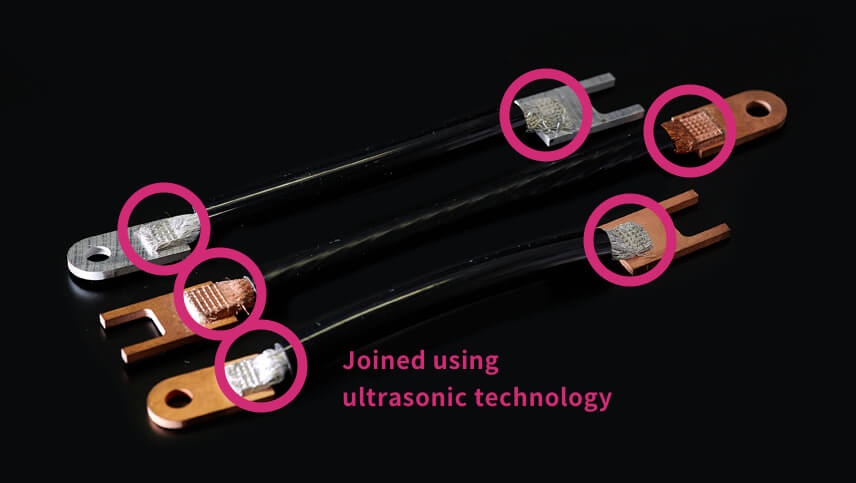

Fexible Busbar Cable

We developed the Flexible Busbar Cable to efficiently carry heavy current for power applications by using ultrasonic joining technology.

Free cable routing in tight spaces by insulated and flexible cables. No special dies are required for individual parts as was the case with conventional pressed busbars. Contributing to increased design freedom and downsizing of the unit.

Features

Aim

Proposal of new values by substituting the manufacturing methods utilizing the advantage of FCC cores.

Overview

Positively contributing to design freedom, assembly workability, durability, and cost by using flexible cables.

VISION

Future Technology Prospects

Application examples