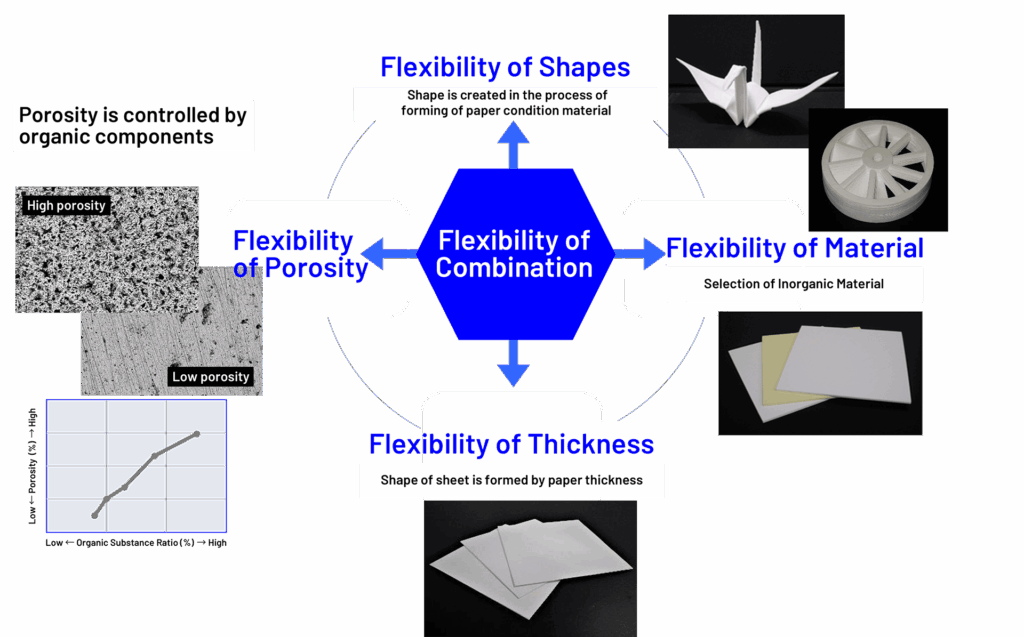

Potential of Functional Ceramics made possible by Flexible Ceramic Paper Design Technology

Flexible paper forming process becomes possible from ceramic paper design technology

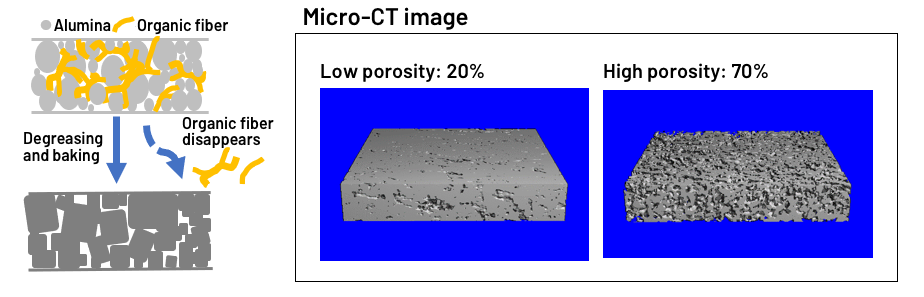

Control of pores by organic additives

・Paper element contained in paper ceramics burns out when the material is heated.

Porosity (gas and liquid permeability, and thermal conductivity) can be controlled adjusting size and numbers of pores utilizing characteristic that the material burned out forms a void.

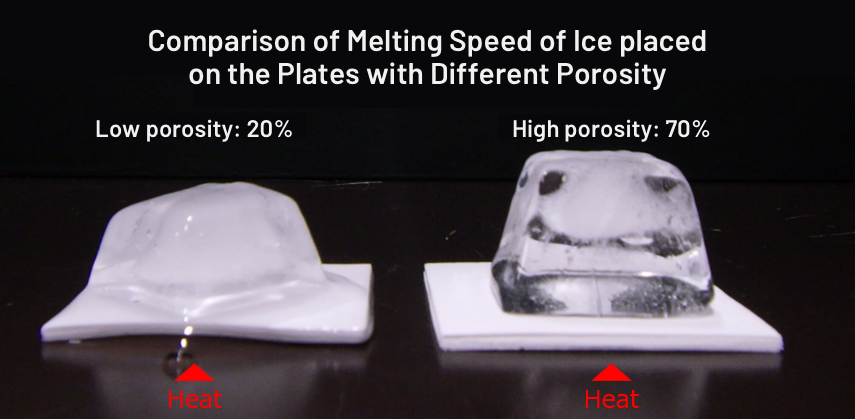

Ceramic heat insulation material

Excellent thermal insulation performance is demonstrated based on high porosity nature as a paper while maintaining incombustibility as a ceramic.

Technology and Development

Related Articles

Potential of Functional Ceramics made possible by Flexible Ceramic Paper Design Technology

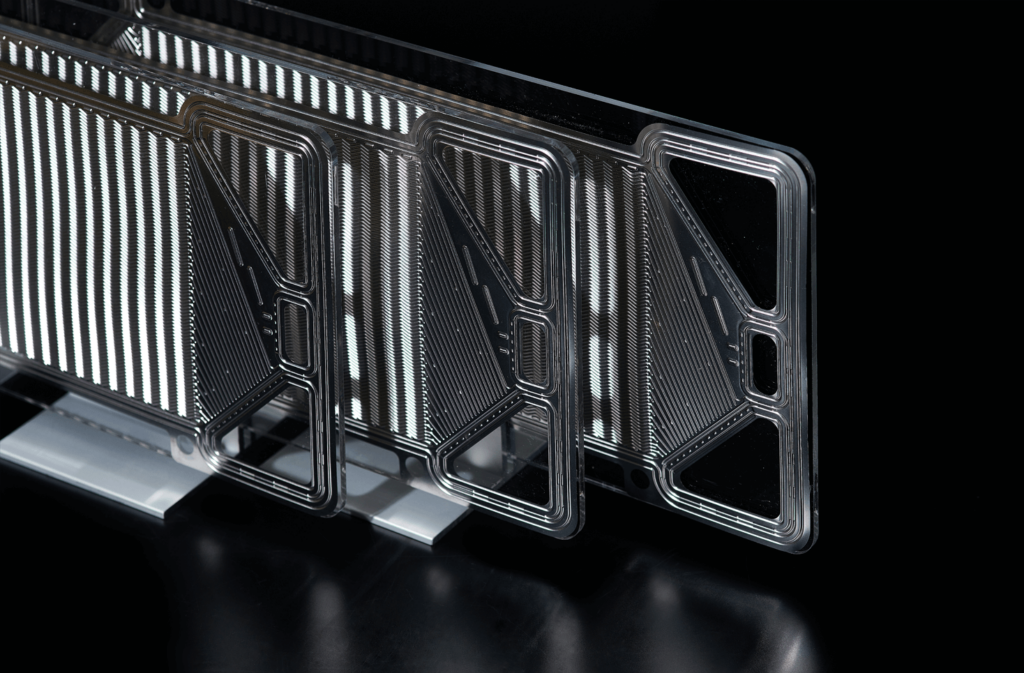

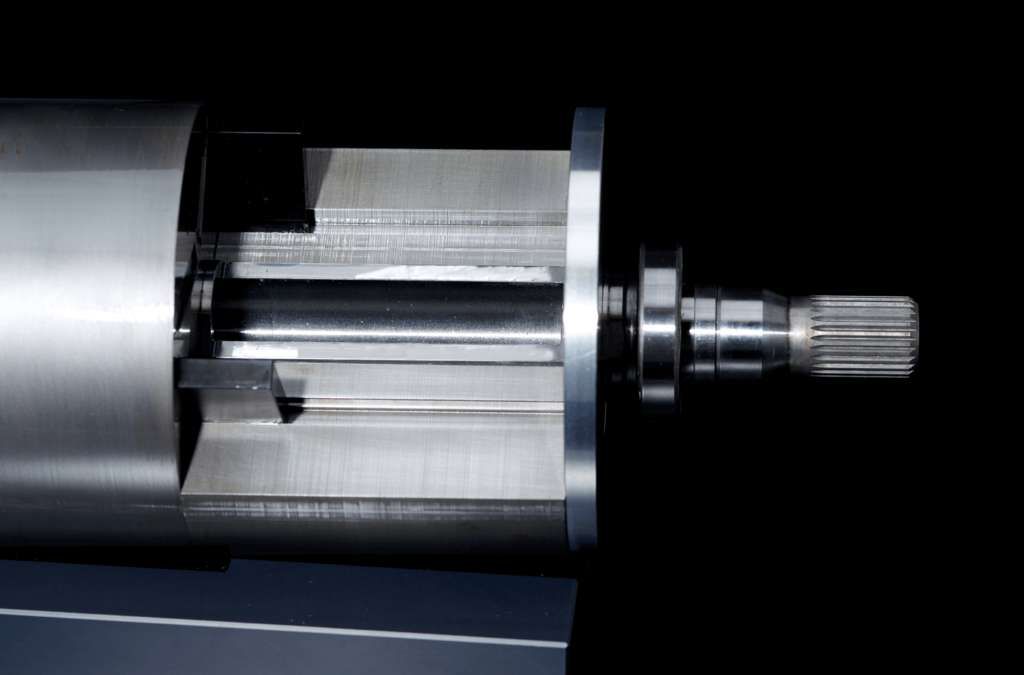

[Manufacturing Patent Pending] Reduction of Manufacturing Costs and Improvement of Cooling Performance are REalized by Hollow Pipe Cast-in Technology