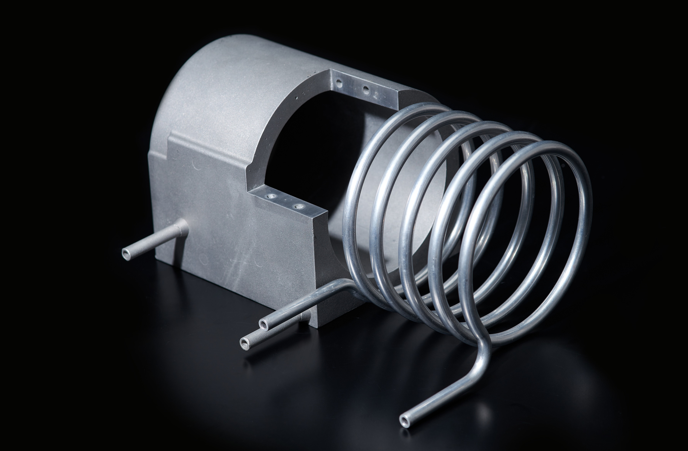

[Manufacturing Patent Pending] Reduction of Manufacturing Costs and Improvement of Cooling Performance are realized by Hollow Pipe Cast-in Technology

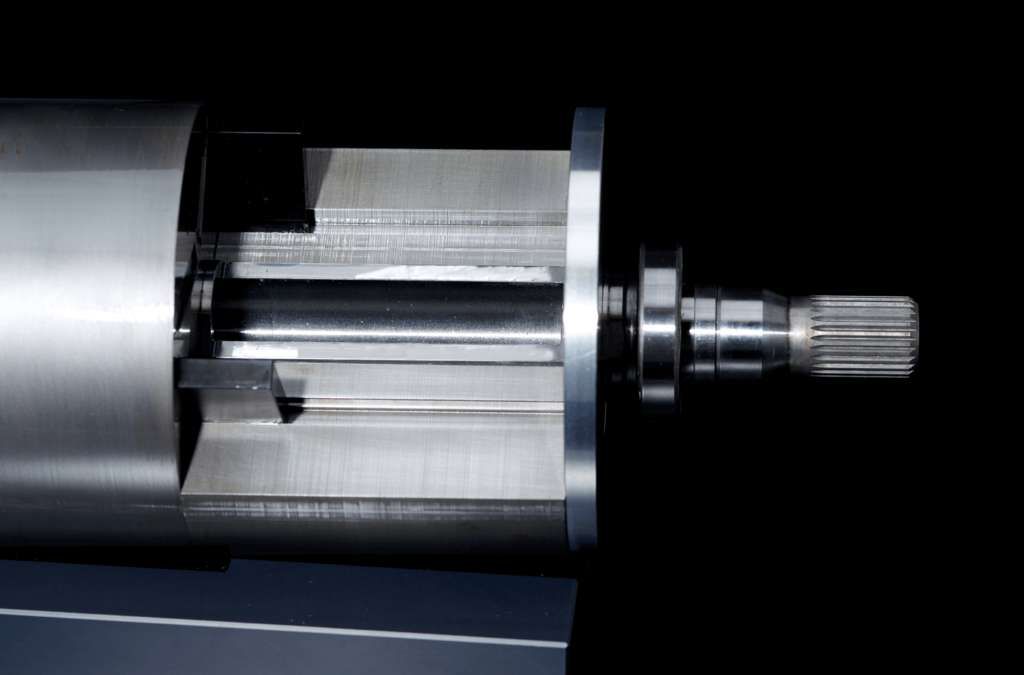

Hollow Pipe Cast-in Technology

Motor Case Sample

Cast-in Technology * Manufacturing Patent Pending

Related Articles

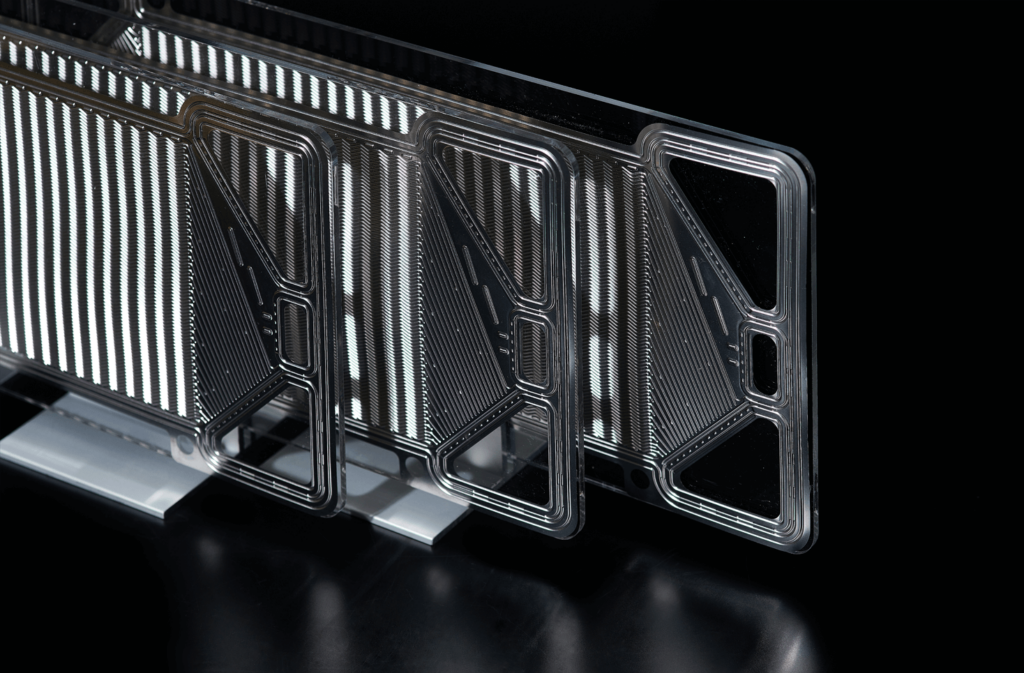

Potential of Functional Ceramics made possible by Flexible Ceramic Paper Design Technology

[Manufacturing Patent Pending] Reduction of Manufacturing Costs and Improvement of Cooling Performance are REalized by Hollow Pipe Cast-in Technology