Rapid prototyping in aluminum casting is the iterative creation of physical prototypes using aluminum as the casting material. This method of creating something enables manufacturers like FCC-NA to validate designs and concepts promptly before scaling up production.

Importance in Manufacturing

Rapid prototyping is crucial in modern manufacturing by accelerating product development cycles and reducing time-to-market. It enables manufacturers to prototype and iterate designs rapidly based on real-world testing and feedback, enhancing product quality and innovation.

As we explore the rapid prototype casting of aluminum this article aims to give you a better understanding of this landscape so that you can leverage its moving parts to work for you. Here at FCC-NA, we strive to make innovative technology work for the benefit of our customers, especially through our advanced clutch products.

Learn More About Our New Technologies Today!

Fundamentals of Aluminum Casting

Aluminum casting stands as a cornerstone in modern manufacturing, leveraging the versatility and advantageous properties of aluminum alloys to create intricate and durable components. This process, where molten aluminum is meticulously poured into molds to achieve precise shapes upon solidification, finds extensive application across multiple industries.

Advantages of Aluminum in Casting

Aluminum’s advantages include:

- Lightweight: Offers significant weight reduction compared to other metals.

- Excellent Castability: Fills complex mold cavities well.

- Corrosion Resistance: Provides good resistance to corrosion in many environments.

- Machinability: Easy to machine and shape further after casting.

- Recyclability: Environmentally friendly due to its high recyclability.

These advantages make aluminum casting ideal for a wide range of applications from automotive components to aerospace parts.

Understanding Rapid Prototyping Techniques

Product development sees rapid prototyping as a revolutionized approach as it offers expedited timelines and cost-effective solutions.

Traditional Prototyping vs. Rapid Prototyping

Unlike conventional methods that often entail lengthy lead times and substantial expenses for production parts, rapid prototyping harnesses cutting-edge manufacturing technologies to swiftly fabricate prototypes. Extensive research has identified that rapid prototyping has much faster and more cost-effective techniques that create prototypes directly from digital models.

Types of Rapid Prototyping Techniques

Rapid prototyping techniques encompass a spectrum of advanced manufacturing processes designed to streamline the creation of prototypes and the manufacture of functional parts. Among these methods are:

- 3D Printing: Additive manufacturing technique that builds layers of material to create a three-dimensional object.

- Investment Casting: A wax pattern is used to create a mold into which molten metal is poured, allowing for complex geometries in investment casting.

- Sand Casting: The process of sand casting uses sand as the mold material, offering flexibility and cost-effectiveness for producing large and complex parts.

The Role of Aluminum in Rapid Prototyping

Using an aluminum cast in rapid prototyping leverages its unique properties to facilitate swift and efficient development cycles.

Properties of Aluminum in Casting

Aluminum’s properties such as its low density, combined with high strength and excellent thermal properties, make it an ideal choice for producing lightweight yet durable prototypes.

Suitability for Rapid Prototyping

In casting processes, aluminum’s properties allow for quick iteration cycles with minimal tooling changes. Its machinability and casting characteristics enable rapid production of complex shapes, facilitating efficient design modifications. This agility is critical in accelerating product development timelines, as designers can swiftly test and refine designs without prolonged manufacturing delays.

By leveraging aluminum in rapid prototyping, manufacturers and designers can streamline innovation. They can optimize the development process, reduce time-to-market, and ensure the delivery of robust solutions that meet performance criteria effectively. This makes aluminum a preferred material in industries where rapid iteration and quick adaptation are essential for achieving competitive advantages.

Learn More About Our Precision Aluminum Casting Technology Today!

Benefits of Rapid Prototyping in Aluminum Casting

Rapid prototyping has emerged as a cornerstone in aluminum casting, offering a multitude of advantages that revolutionize the manufacturing landscape. Chief among these benefits are:

Time Efficiency

Rapid prototyping accelerates the product development cycle by significantly reducing lead times. Compared to traditional methods that require extensive tooling and setup, rapid prototyping has been observed to allow for quick fabrication of prototypes. This speed enables manufacturers to validate concepts swiftly and iterate designs based on feedback, ultimately speeding up time-to-market.

Cost-effectiveness

Traditional manufacturing processes often involve high upfront costs for tooling and setup. Rapid prototyping minimizes these expenses by using digital designs directly to create molds or patterns, bypassing the need for expensive tooling. Additionally, it reduces material waste since prototypes can be produced precisely as needed, further lowering overall production costs.

Design Flexibility

One of the most significant advantages of rapid prototyping in aluminum casting is its ability to explore complex geometries and design variations. Manufacturers can test multiple iterations of a design quickly and efficiently, without being constrained by the limitations of traditional manufacturing methods. This flexibility encourages innovation and allows for the optimization of product performance and functionality.

These benefits collectively enhance innovation, efficiency, and competitiveness within the aluminum casting industry. By leveraging rapid prototyping, manufacturers can streamline their processes, respond more effectively to market demands, and achieve higher levels of manufacturing excellence.

Learn More About Our Precision Aluminum Casting Technology Today!

Challenges and Limitations

While rapid prototype castings in manufacturing offer substantial benefits, it also presents several challenges and limitations that engineers and designers must navigate.

Surface Finish and Accuracy

Achieving precise surface finishes and dimensional accuracy can be challenging with rapid prototype and casting methods. Processes such as 3D printing or rapid casting may produce rougher surfaces or slight dimensional variations that require post-processing to meet high-quality standards. This additional refinement adds time and cost to the final production process.

Material Selection Constraints

Rapid prototyping methods may have limitations in material selection compared to traditional casting techniques. While there are aluminum alloys available for rapid prototyping, the range of options may be narrower, and specific material properties such as strength or corrosion resistance could be more limited. Designers must balance the available material options with the requirements of the application.

Post-Processing Requirements

Many rapid prototype castings and assembly processes require post-processing to achieve the desired mechanical properties and surface finishes. This can involve secondary operations such as heat treatment, machining, or surface treatment, which add complexity to the production cycle and may affect overall lead times.

Addressing these challenges requires careful planning and integration of complementary processes. Advanced CAD/CAM technologies, improved material formulations, and innovative post-processing techniques are continuously evolving to mitigate these limitations, thereby optimizing both product quality and production efficiency.

Applications of Rapid Prototyping in Aluminum Casting

Rapid prototyping in aluminum casting finds diverse and crucial applications across industries, leveraging metal and its unique capabilities to innovate and advance various sectors.

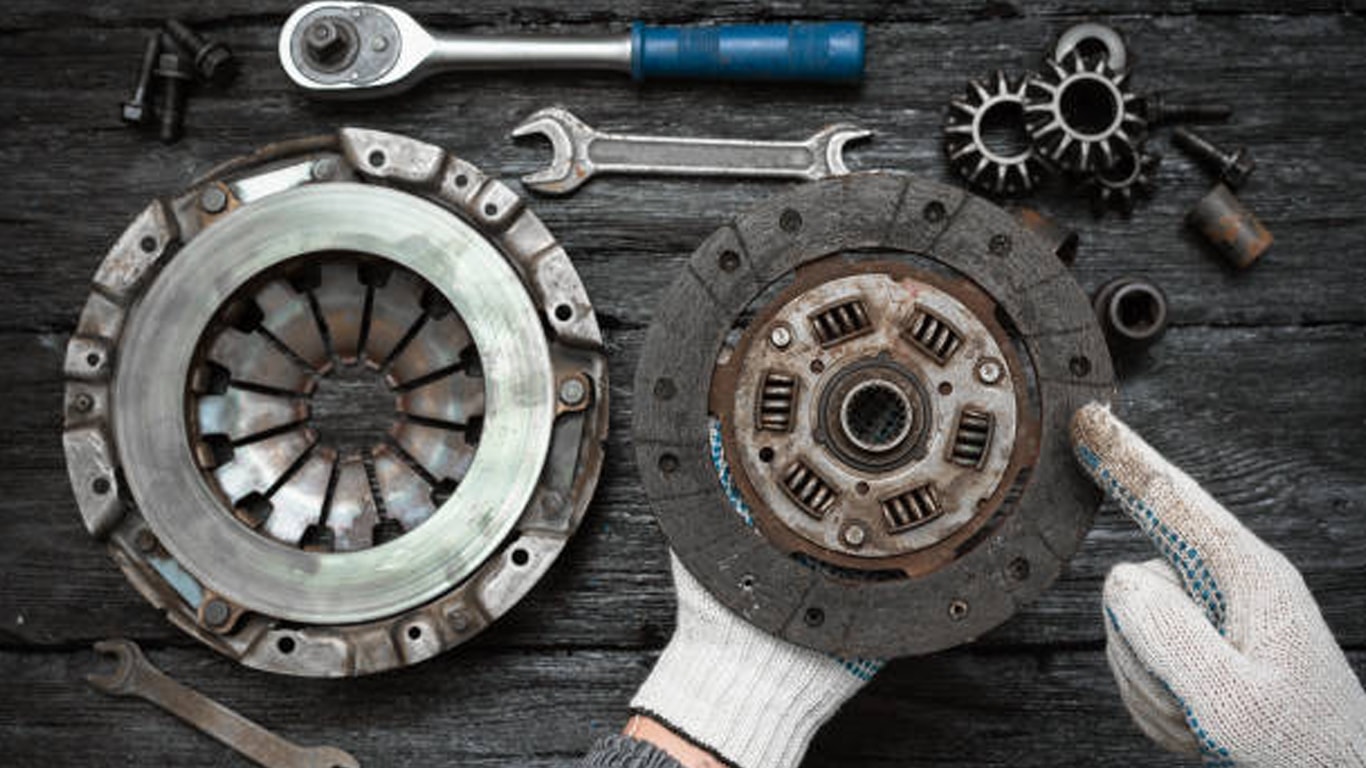

Automotive Industry

In automotive manufacturing, rapid prototyping is integral for developing engine components, lightweight structures, and complex assemblies. It enables engineers to quickly iterate designs, optimize performance, and validate concepts before full-scale production. This agility is crucial in enhancing vehicle efficiency, safety, and overall design innovation.

Aerospace Sector

Similarly, rapid prototype casting plays a vital role in the aerospace industry by facilitating the development of aircraft components. These components often require lightweight materials like aluminum to improve fuel efficiency and performance. Rapid prototyping allows for the rapid iteration of designs, ensuring that aerospace engineers can prototype parts that meet stringent safety standards while pushing the boundaries of structural integrity and weight reduction.

Medical Device Manufacturing

In the medical field, rapid prototyping in aluminum casting enables the efficient development of medical implants and devices. This technology supports rapid customization to meet patient-specific needs while adhering to strict regulatory requirements for performance and biocompatibility. It accelerates the product development timeline, allowing medical device manufacturers to introduce new solutions faster and more effectively.

These applications demonstrate how rapid prototyping in aluminum casting drives innovation across various sectors, from improving automotive performance to enhancing aerospace capabilities and advancing medical technology. By leveraging prototype casting and its capabilities for rapid iteration and design optimization, industries can achieve significant advancements in product development, efficiency, and competitiveness on a global scale.

Success Metrics and Performance Indicators

Success in rapid prototyping initiatives hinges on a range of critical metrics that evaluate efficiency, effectiveness, and overall impact.

Measuring Success in Rapid Prototyping Initiatives

Success can be measured by:

Reduced Time-to-Market

One of the primary metrics for success in rapid prototype castings is the reduction in time-to-market. This metric measures how quickly a product can move from initial concept to market launch. Rapid prototyping allows for faster iteration and validation of designs, enabling companies to respond swiftly to market demands and gain a competitive edge.

Cost Savings

Cost-effectiveness is another crucial measure of success. Rapid prototyping can lead to significant savings by minimizing material waste, reducing tooling costs (if applicable), and optimizing production processes. These savings contribute directly to improving overall profitability and return on investment.

Product Performance

The effectiveness of rapid prototyping is also evaluated based on how well prototypes meet design specifications and functional requirements. The ability to produce prototypes that accurately simulate final product performance helps in identifying and addressing design flaws early in the development cycle.

Customer Satisfaction

Ultimately, the success of rapid prototyping initiatives is reflected in customer satisfaction. Positive feedback from end-users and stakeholders indicates that the rapid prototypes used are meeting market needs and expectations. Customer satisfaction metrics include acceptance rates, feedback on usability, and perceived value. reduced time-to-market, cost savings, improved product performance, and customer satisfaction.

With over 29 strategically placed global manufacturing facilities and the no. 1 motorcycle clutch global share, FCC clutches has capitalized on innovation and technology to bring high-quality precision aluminum casted products to the world. Our continuous focus is on making our products top-notch in quality, lighter in weight, quicker to deliver, and more budget-friendly.

Learn More About Our Precision Aluminum Casting Technology Today!

Key Performance Indicators (KPIs)

KPIs are metrics that collectively guide decision-making, drive continuous improvement, and ensure that rapid prototype castings and initiatives achieve their intended goals effectively. They include:

- Prototype Lead Time: Measures the time taken to produce a prototype from initial design to completion. Shorter lead times indicate higher efficiency in the prototyping process.

- Material Utilization Efficiency: Evaluate how effectively materials are used during prototyping. Higher efficiency means less material waste, contributing to cost savings and sustainability.

- Defect Rates: Tracks the occurrence of defects or deviations from design specifications in prototypes. Lower defect rates indicate higher quality and reliability of prototypes.

- Overall Project Costs vs. Budget: Compares the actual costs incurred during the prototyping phase against the budgeted costs. Effective cost management ensures that projects remain within financial constraints while delivering desired outcomes.

Summary of Key Points

Rapid prototyping in aluminum casting offers significant advantages in time efficiency, cost-effectiveness, and design flexibility, despite challenges in surface finish and material limitations. However, rapid prototype metal castings can have accelerated innovation and improved competitiveness in industries ranging from automotive to aerospace.

For more than 80 years, FCC has stayed ahead of industries to keep our Core Technologies and Core Products innovative. Rapid prototyping in aluminum casting is just one technology we leverage to enhance our product development and facilitate faster adaptation to market demands.

Start Leveraging Our Precision Aluminum Casting Technology Today!