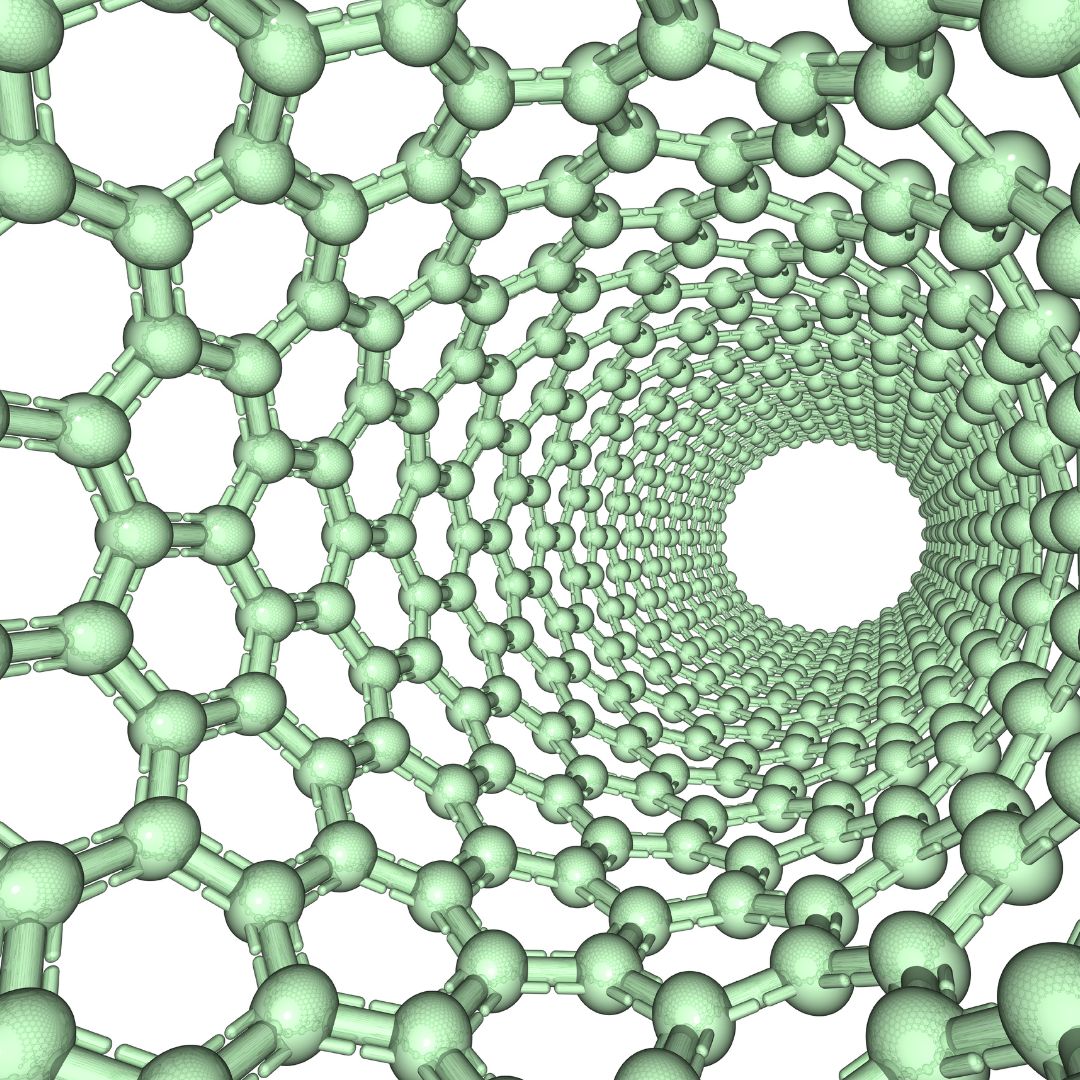

Carbon nanotubes (CNTs) are cylindrical molecules that consist of rolled-up sheets of single-layer carbon atoms (graphene). They exhibit remarkable physical properties, such as exceptional strength, unique electrical properties, and efficient heat conduction, making them potentially useful in a myriad of applications across various industries. These properties have positioned carbon nanotubes as a pivotal material in the fields of nanotechnology, electronics, optics, and other materials science domains. Their significance lies not only in their unique characteristics but also in their potential to revolutionize industries ranging from healthcare, with targeted drug delivery systems, to aerospace, with stronger and lighter materials. In this blog post, we will traverse the competitive landscape and future trends in carbon nanotube research. We’ll start by unpacking the history of CNTs, from their discovery to the present day, to understand the foundation of their development. Then, we’ll explore the groundbreaking advancements in carbon nanotube synthesis, characterization, and application.

Historical Context of Carbon Nanotubes

The exploration of carbon nanotubes (CNTs) is a tale of scientific curiosity and groundbreaking discoveries that have spanned decades.

Discovery and Early Research

The official discovery of carbon nanotubes can be traced back to 1991 when Sumio Iijima, Akira Koshio & Masako Yudasaka, Japanese scientists, identified multi-walled carbon nanotubes using a transmission electron microscope. This seminal discovery was not the beginning, however, as early observations and studies hinting at nanostructures resembling carbon nanotubes date back to the 1950s and 60s.

The early research focused on understanding the structure and properties of these nanotubes, with scientists exploring various methods of synthesizing and manipulating them. The groundbreaking nature of Yudasaka and team’s discovery lay in the visualization and identification of these structures as distinct entities, sparking a global carbon nanotubes market and interest in their potential applications.

Milestones in Development

Following the discovery of carbon nanotubes, the 1990s and early 2000s witnessed several key milestones that propelled CNT research forward. One of the significant developments was the invention of methods for producing single-walled carbon nanotubes (SWCNTs), which have distinctive properties compared to their multi-walled counterparts.

Techniques such as arc discharge, laser ablation, and chemical vapor deposition became crucial in synthesizing high-quality CNTs. Another milestone was the discovery of carbon nanotubes’ exceptional strength, with CNTs being identified as one of the strongest materials known. Additionally, the ability to manipulate the electrical properties of carbon nanotubes opened new doors for their use in nanoelectronics.

Current State of Carbon Nanotube Research

The space of carbon nanotube (CNT) research is perpetually advancing, with recent years witnessing exponential growth in knowledge and applications in different market segments.

Key Areas of Focus

Research on carbon nanotubes is currently concentrated in several critical areas, aiming to overcome existing challenges and unlock new potential.

One primary focus is on improving the methods for the synthesis of CNTs to achieve higher purity and better control over their properties, such as length, chirality, and alignment. Another significant area of research is the integration of CNTs into composite materials such as fiber/epoxy composites, aiming to harness their exceptional strength and high electrical conductivity for use in aerospace, automotive, and construction materials.

Additionally, there is an intense interest in developing CNT-based electronic devices, including transistors, sensors, and energy storage systems, The goal is to achieve higher performance than current technologies allow. In the biomedical field, the focus is on exploiting the unique properties of CNTs for drug delivery, bio-imaging, and tissue engineering applications.

Leading Researchers and Institutions

The landscape of carbon nanotube research is populated by numerous distinguished researchers and institutions. The Massachusetts Institute of Technology (MIT), Rice University, and Stanford University are at the forefront, with their research teams making significant contributions to the development of CNT technology.

Internationally, the National Institute for Materials Science in Japan and the Cambridge Graphene Centre in the UK are leading research hubs focusing on advancing CNT synthesis and applications. These institutions not only contribute to basic research but also collaborate with industrial partners to accelerate the transition from laboratory discoveries to real-world applications.

Notable Breakthroughs and Innovations

In recent years, several future trends in carbon nanotube research have captured the scientific community’s attention.

One of the most significant breakthroughs was the development of a scalable chemical vapor deposition (CVD) process for producing high-quality, single-walled carbon nanotubes, which has greatly facilitated their commercial use.

Another notable innovation is the creation of the first CNT-based computer processor, demonstrating the potential of CNTs to revolutionize the electronics industry. These breakthroughs underscore the versatility and immense potential of carbon nanotubes to transform a wide range of industries.

Future Trends in Carbon Nanotube Research

The research of carbon nanotube (CNT) continues to evolve, with emerging trends highlighting innovative approaches and broadening the scope of applications.

Advanced Manufacturing Techniques

Advanced manufacturing techniques are continuously being developed to improve the quality, yield, and cost-effectiveness of CNT production.

1. Growth Methods

Recent advancements in CNT growth methods include refined chemical vapor deposition (CVD) techniques, which now allow for more precise control over the nanotubes’ diameter, length, and alignment. Innovations such as floating catalyst CVD further enhance the yield and quality of CNTs, making large-scale production more feasible and cost-effective.

2. Purification Processes

Purification processes have seen significant improvements in removing amorphous carbon and metal catalysts, which can affect the purity and electrical properties of CNTs. Techniques such as microfiltration, centrifugation, and acid treatment have become more sophisticated, enabling the production of CNTs with higher purity levels essential for specific applications.

Novel Applications and Industries

CNTs are finding new applications and use cases in various industries, including energy storage, healthcare, and environmental remediation. Here are some notable examples:

1. Biomedical Applications

In the biomedical sector, CNTs are being explored for use in drug delivery systems and as scaffolds for tissue engineering. Their unique properties enable them to traverse biological barriers, deliver therapeutic agents directly to targeted sites, and support the growth of cells for tissue regeneration.

Energy Storage and Conversion

CNTs are revolutionizing the field of energy, particularly in storage and conversion technologies such as batteries and supercapacitors. Their exceptional electrical conductivity and large surface area enhance the performance and efficiency of energy storage systems, paving the way for more sustainable energy solutions.

Challenges and Limitations

Despite the promising advancements and potential applications of carbon nanotubes (CNTs), several challenges and limitations remain that could hinder their broader adoption. Addressing these issues is crucial for the sustainable development and commercialization of CNT-based technologies.

Scalability and Production Costs

A significant obstacle facing CNT technology is the difficulty in scaling up production methods without inflating costs. While advancements in chemical vapor deposition (CVD) and other synthesis techniques have improved yield and quality, the production of CNTs on an industrial scale remains expensive due to high energy requirements and the complexity of purification processes. Reducing production costs while maintaining or enhancing the quality of CNTs is essential for their integration into mainstream applications.

Toxicity and Environmental Impact

The potential toxicity and environmental impact of CNTs pose another challenge. Preliminary studies have raised concerns about the health risks associated with inhalation of CNT particles, similar to those observed with fine particulate matter. Furthermore, the durability of CNTs, while beneficial for product lifespan, raises questions about their biodegradability and the consequences of their accumulation in the environment. Addressing these concerns requires comprehensive toxicological studies and the development of safe handling and disposal protocols.

Regulatory Hurdles and Standards

The lack of standardized regulations and protocols for the safe production, use, and disposal of CNTs represents a significant hurdle. Without uniform standards, it is challenging to assess the safety, quality, and environmental impact of CNT-based products, potentially hindering carbon nanotubes market growth, acceptance and application. Establishing regulatory frameworks and international standards is critical for fostering innovation while ensuring public health and environmental protection.

Summary of Future Trends in Carbon Nanotube Research

The future trends in carbon nanotube research continue to offer promising avenues for a variety of applications across industries. From enhancing energy storage solutions to pushing the boundaries of biomedical applications, CNTs represent a frontier of innovation and sustainable development. However, overcoming the challenges of scalability, environmental impact, and regulatory standards remains crucial for the future integration of CNT technologies.

At FCC, we are committed to leveraging cutting-edge technologies to deliver superior solutions to our clients. Our dedication to innovation and sustainability positions us as a leading partner in the realm of advanced materials and manufacturing processes.

Discover how FCC’s expertise can empower your projects with advanced material solutions.

Learn More About Our Clutch Housing Manufacturing Process Today!