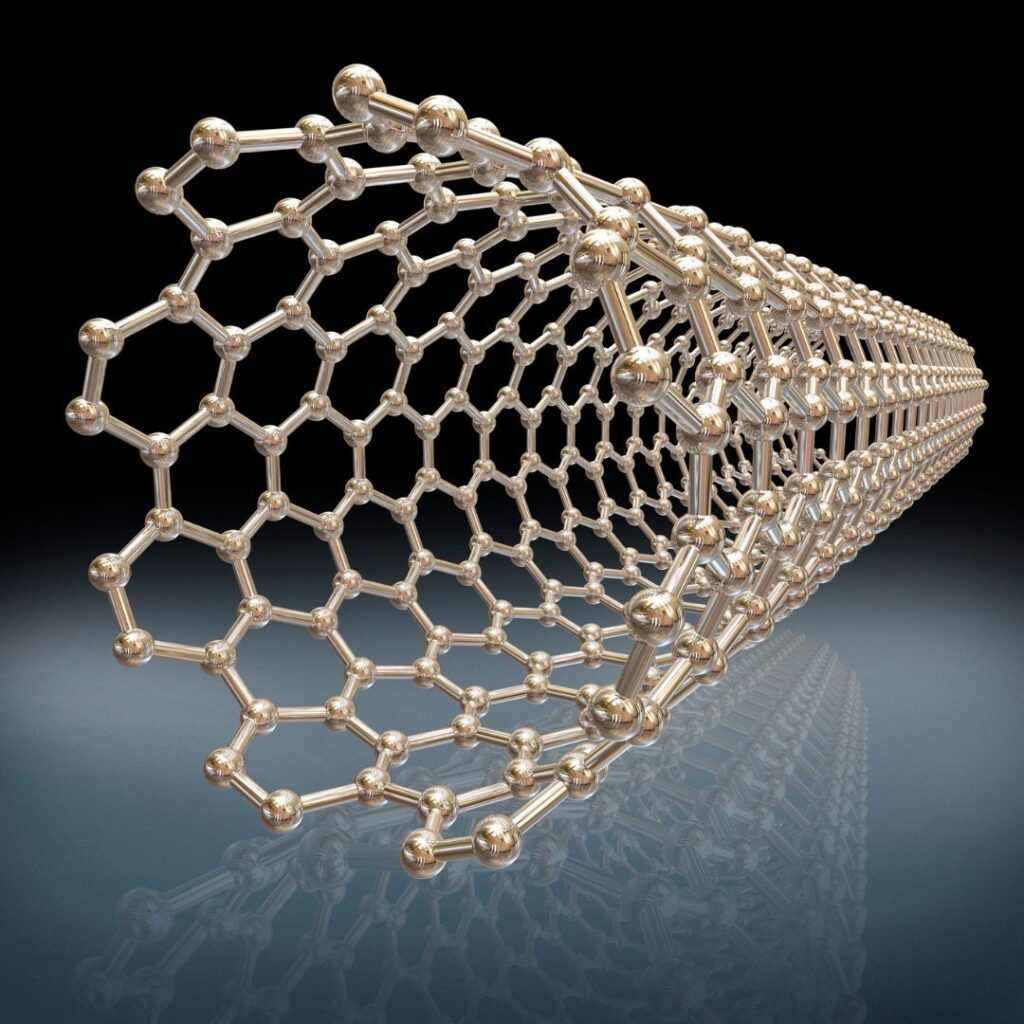

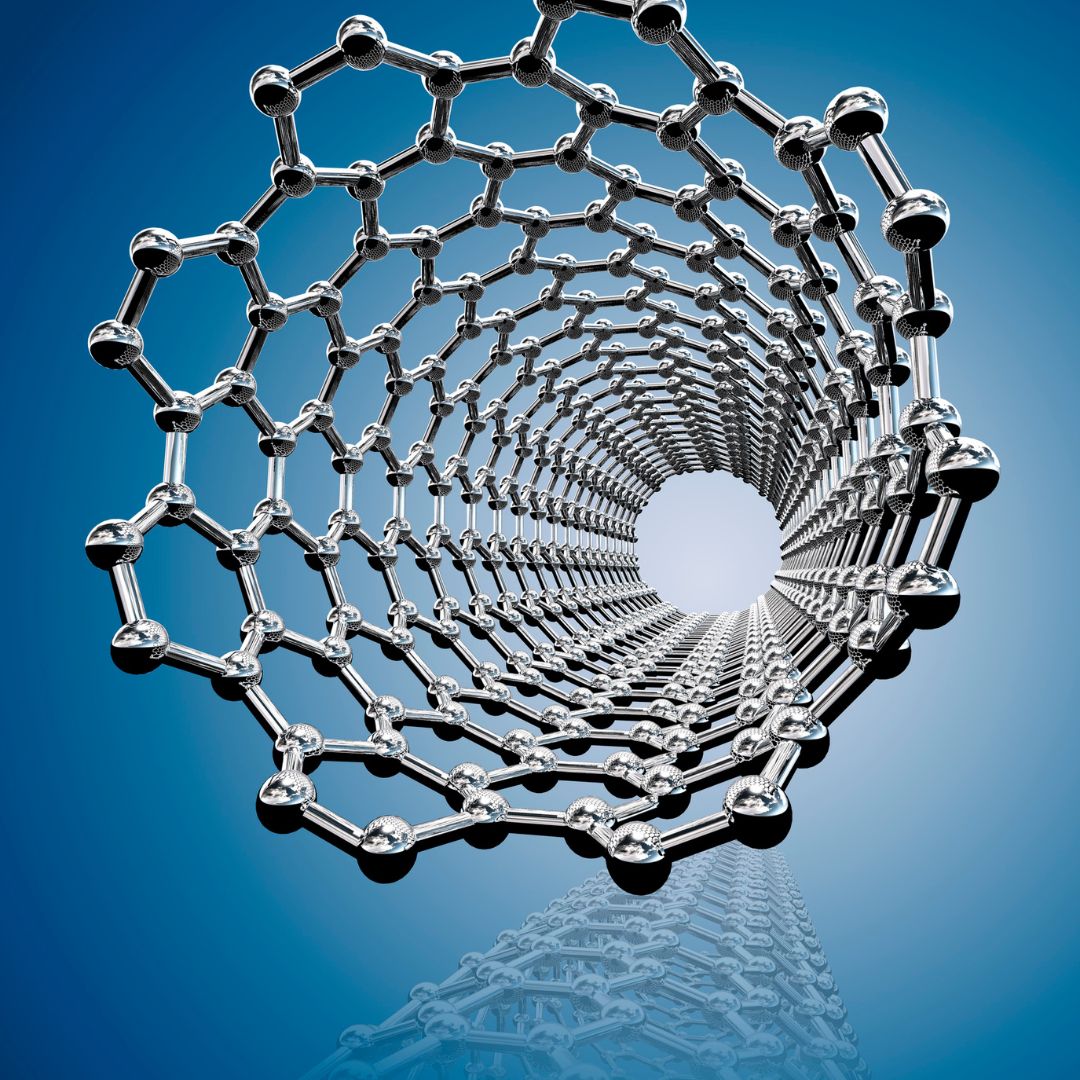

In this article, we will explore the framework of carbon nanotubes. To do so, however, we will first have to understand what carbon nanotubes are. So what are carbon nanotubes? Carbon nanotubes (CNTs) are cylindrical structures formed from single sheets of graphene, with Sumio Iijima’s discovery in 1991 marking a significant milestone in nanotechnology to form carbon nanotubes. These structures, including single-walled nanotubes (SWNTs), double-walled nanotubes (DWNTs), and multi-walled nanotubes (MWNTs), offer diverse properties such as high electrical conductivity, mechanical strength, stability, chemical resistance, thermal conductivity, and load-bearing capacity.

Tailoring the diameter, chirality, and functionalization of carbon nanotubes allows for precise customization to suit various applications across electronics, composites, medicine, and energy storage solutions, making them highly sought-after materials in scientific research, automotive components, and technological innovation.

For over 80 years, FCC has been driven by innovation and finding solutions for present and future challenges. Our revolutionary development and manufacturing processes set us apart to maximize the safety, quality, cost, and delivery of our innovative clutch technology.

Learn More About FCC’s Advanced Clutch Technology

Significance in Modern Science

What are carbon nanotubes and what is their significance in modern science? Carbon nanotubes are versatile materials of carbon fibers with vast potential across scientific fields. In electronics, their high conductivity enables use in carbon nanotube transistors and interconnects, promising faster and more efficient devices. The strength and lightweight properties of their composites however enhance materials for aerospace, automotive, and sporting goods, with added electrical conductivity benefits.

Carbon nanotubes in medicine offer biocompatibility for targeted drug delivery and biosensing, as well as potential in tissue engineering. Their structure and energy storage capabilities also make them ideal for electrodes in supercapacitors and batteries and for hydrogen storage. Additionally, carbon nanotubes show promise in water desalination, displays, and catalyst supports.

However, challenges like production scalability, cost, and safety concerns must be addressed for widespread adoption.

What Are Carbon Nanotubes: Structure

Understanding the structure of carbon nanotubes and what are carbon nanotubes, unlocks their potential. So what are carbon nanotubes on a structural level? Their unique atomic arrangement and bonding give them remarkable strength, conductivity, and other properties, paving the way for advancements.

Atomic Composition

Carbon nanotubes consist solely of carbon atoms, arranged in a precise manner that underpins their extraordinary characteristics. Single-walled carbon nanotubes (SWNTs) are composed of a single-atom-thick sheet of graphene, rolled seamlessly into a cylindrical structure, while multi-walled nanotubes (MWNTs) exhibit nested layers of graphene sheets wrapped around each other, offering a more complex yet equally fascinating atomic composition.

Bonding Arrangements

The remarkable properties of carbon nanotubes stem from the robust covalent bonds between carbon atoms. Through sp² hybridization, each carbon atom forms three strong sigma bonds with neighboring carbon atoms within the same graphene sheet, resulting in a planar structure characteristic of carbon nanotubes. Additionally, in multi-walled nanotubes, weaker van der Waals interactions between stacked graphene layers allow for some sliding and rotation, contributing to the unique properties and behaviors of these structures.

The way the graphene sheet is rolled dictates the “chirality” of the nanotube structure, influencing its electronic and optical properties.

Unique Physical Properties

A research team led by Dr. Bon-Choel Ku was able to break down “What are carbon nanotubes?” and identify that the unique physical properties of carbon nanotubes result from their atomic composition and bonding arrangements, offering exceptional characteristics with diverse applications. With covalent bonds providing exceptional strength, carbon nanotubes surpass steel in strength per weight. Their high electrical conductivity, influenced by chirality, allows for efficient electron transport, with single-walled nanotubes (SWNTs) exhibiting metallic or semiconducting behavior.

Carbon nanotubes also demonstrate low thermal expansion, maintaining their shape under extreme temperature changes. They boast a high surface area due to their hollow, cylindrical structure, facilitating adsorption and chemically modified reactions. Moreover, their properties are tunable through variations in diameter, chirality, and functionalization, enabling tailored applications across scientific fields.

What are Carbon Nanotubes: Types

Carbon nanotubes come in various types, each with distinct characteristics and applications, shaping their versatility and widespread use in diverse fields of science and technology.

Single-Walled Carbon Nanotubes (SWCNTs)

Single-walled carbon nanotubes are cylindrical nanostructures composed of a single layer of carbon atoms arranged in a hexagonal lattice. They can be thought of as rolled-up graphene sheets, forming seamless tubes with diameters typically ranging from about 0.4 to 2 nanometers. single-walled carbon nanotubes exhibit remarkable electrical and thermal conductivity, as well as unique optical properties. Their electronic properties can vary significantly depending on their chirality, making them suitable for applications in electronics, optoelectronics, and sensors.

Single-walled carbon nanotubes are also promising candidates for nanoscale devices, such as field-effect transistors, due to their high carrier mobility and quantum confinement effects. According to Market Research, the U.S. electrical, electronics, and automotive industries consume a considerable amount of single-wall carbon nanotubes. The U.S. currently holds a major share of the regional single-wall carbon nanotubes market.

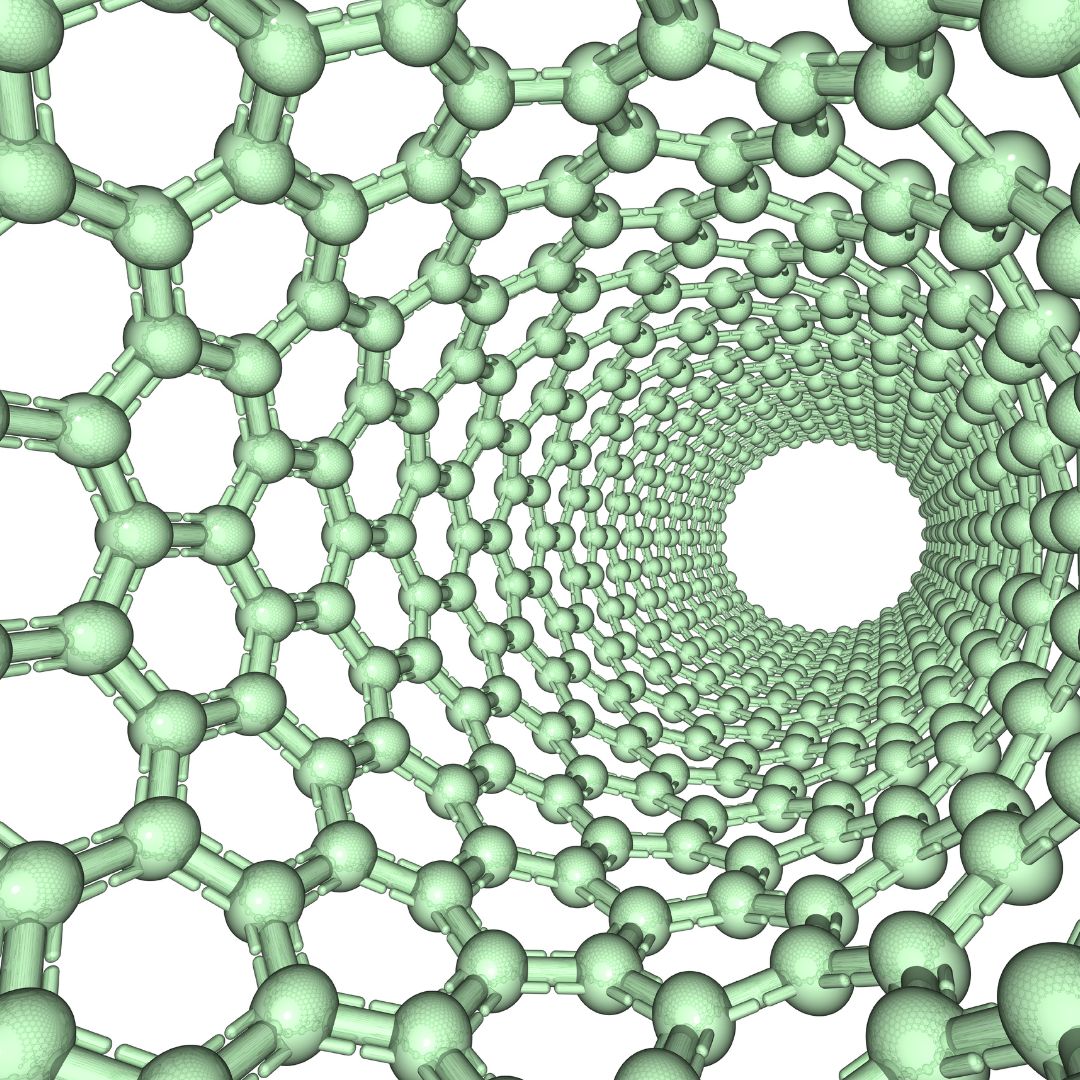

Multi-Walled Carbon Nanotubes (MWCNTs)

Multi-walled nanotubes consist of multiple concentric layers of carbon atoms arranged in cylindrical tubes. These layers are held together by van der Waals forces, creating a structure reminiscent of nested Russian dolls. Multi-walled nanotubes typically have larger diameters than single-walled carbon nanotubes, ranging from around 2 to 100 nanometers.

Multi-walled carbon nanotubes exhibit excellent mechanical strength improvement properties, including high tensile strength and flexibility, making them suitable for reinforcing composite materials. Multiwall carbon nanotubes find applications in a wide range of fields, including aerospace, automotive, and energy storage, where their lightweight and robust nature is advantageous.

Chirality and Its Influence

Chirality refers to the helical arrangement of carbon atoms within a nanotube, significantly influencing its electronic properties. single-walled carbon nanotubes can exhibit either metallic or semiconducting behavior, depending on their chirality. Metallic single-walled carbon nanotubes have a high electrical conductivity and are ideal for applications requiring low resistance, such as interconnects in electronic devices.

Semiconducting single-walled carbon nanotubes, on the other hand, have a bandgap that allows for the modulation of electrical conductivity between carbon atoms, making them suitable for transistors and other electronic components. The ability to selectively synthesize single-walled carbon nanotubes with specific chiralities is crucial for tailoring their properties and optimizing their performance in various applications.

Synthesis Methods

Synthesis methods play a crucial role in the production of carbon nanotubes, dictating their properties and suitability for specific applications.

Arc Discharge

Arc discharge is one of the earliest methods used for synthesizing carbon nanotubes and remains relevant today. In this process, a high-voltage electric arc is generated between two carbonaceous electrodes of carbon atoms in an inert atmosphere, typically helium. The intense heat produced vaporizes the carbon source, leading to the formation of carbon nanotubes in the soot deposited on the cooler electrode.

Arc discharge is capable of producing both single-walled and multi-walled carbon nanotubes, although the resulting product often contains impurities and requires post-processing to purify the nanotubes. Despite its simplicity, arc discharge is limited by its low yield and scalability.

Chemical Vapor Deposition (CVD)

Chemical vapor deposition is a widely used method for synthesizing high-quality carbon nanotubes with precise control over their properties. In chemical vapor deposition, a carbon-containing gas, such as methane or ethylene, is introduced into a high-temperature reactor along with a catalyst, typically transition metals like iron, cobalt, or nickel. The carbon atoms from the gas decompose on the surface of the catalyst particles, leading to the growth of carbon nanotubes.

Chemical vapor deposition offers excellent scalability and control over the chemical properties and synthesis parameters, allowing for the production of aligned arrays of nanotubes with tailored properties. It is the preferred method for industrial-scale production of carbon nanotubes for various applications, including electronics, composites, and energy storage.

High-Pressure Carbon Monoxide (HiPco)

High-pressure carbon monoxide (HiPco) is a synthesis method that utilizes carbon monoxide gas as the carbon source under high pressure and temperature conditions. In the high-pressure carbon monoxide process, a metal catalyst, such as iron pentacarbonyl, is dispersed in a high-pressure reactor along with carbon monoxide gas. Upon heating, the metal catalyst decomposes, leading to the formation of carbon nanotubes through a vapor-phase reaction among the carbon atoms.

High-pressure carbon monoxide is known for producing high-purity single-walled carbon nanotubes with minimal defects. However, it is more challenging to control compared to CVD and is typically used for research purposes rather than large-scale production.

Applications in Materials Science

In discovering carbon nanotubes, subsequent researchers have been able to further identify that carbon nanotubes hold tremendous promise in materials science. This is due to their exceptional mechanical properties, electrical properties, and thermal properties, which continue to pave the way for innovative applications across various fields. The global carbon nanotubes market is currently valued at USD 6.28 Billion and is projected to be valued at USD 17.34 Billion by the end of 2030. That validates the potential of its current and potential uses!

Structural Reinforcement

One of the most significant applications of carbon nanotubes in materials science is their use as reinforcement agents in structural materials. Carbon nanotubes possess remarkable mechanical properties, including high tensile strength and stiffness, which can significantly enhance the mechanical performance of composites. By dispersing carbon nanotubes within polymers, ceramics, or metals, the resulting composite material exhibits improved strength, toughness, and fatigue resistance.

These enhanced properties make carbon nanotube-reinforced composites ideal for applications in aerospace, automotive, construction, and sporting goods industries, where lightweight yet durable materials are in high demand.

In the automobile sector, the trend is towards electrification and heat management. FCC employs aluminum integrated with heat insulation to introduce innovative products. Our utilization of aluminum die casting extends to various applications, including motorcycles. These applications highlight FCC’s core technological strengths, exemplified by the intricate detailing within the clutch mechanism, which extensively utilizes this technology.

Learn More About FCC’s Core Technological Automotive Clutches!

Conductive Properties

Carbon nanotubes exhibit excellent electrical conductivity, making them valuable additives in conductive materials and electronic devices. When incorporated into polymers or other matrices, carbon nanotubes form conductive pathways that enable the efficient transport of electrons.

This conductive property finds applications in flexible and transparent conductive films, electromagnetic interference shielding, and electrostatic discharge protection. Carbon nanotube-based conductive materials are also utilized in the development of next-generation electronics, such as flexible displays, touch screens, and wearable devices.

Additionally, carbon nanotube-based electrodes show promise in energy storage and conversion devices, including batteries, supercapacitors, and fuel cells, due to their high surface area and electrical conductivity.

Nanotubes in Composite Materials

Carbon nanotubes can enhance the properties of composite materials across various applications. By dispersing carbon nanotubes within a matrix material, such as polymers, ceramics, or metals, the resulting composites exhibit synergistic properties that surpass those of the individual components.

In addition to structural reinforcement, carbon nanotubes can impart functionalities such as electrical conductivity enhancement, thermal conductivity applications, and electromagnetic shielding to composite materials. This versatility enables the development of lightweight, multifunctional materials tailored for specific applications, including aerospace engineering components, automotive parts, sports equipment, and biomedical engineering devices.

Furthermore, carbon nanotube-based composites show promise in emerging fields such as 3D printing, where precise control over material properties is essential for manufacturing complex structures with high performance.

Medical Applications

Carbon nanotubes hold immense potential for revolutionizing medical applications due to their unique properties, including high surface area, biocompatibility, and tunable surface chemistry.

Drug Delivery Systems

One of the most promising medical applications of carbon nanotubes is in drug delivery systems. Research into drug delivery has shown that functionalized carbon nanotubes can serve as carriers for various therapeutic agents, including drugs, genes, and proteins. The large surface area of carbon nanotubes allows for high drug-loading capacity, while their ability to penetrate cell membranes facilitates targeted delivery to specific tissues or cells.

Additionally, carbon nanotubes can be engineered to release drugs in response to external stimuli, such as pH, temperature, or light, enabling controlled and site-specific drug release. These features offer significant advantages over conventional drug delivery systems, including improved efficacy, reduced side effects, and enhanced bioavailability of therapeutic agents.

Imaging and Diagnostics

Carbon nanotubes also show great promise in the field of medical imaging and diagnostics. Functionalized carbon nanotubes can be conjugated with imaging agents, such as fluorescent dyes or contrast agents, to enhance the visibility of tissues and organs in various imaging modalities, including fluorescence imaging, magnetic resonance imaging (MRI), and computed tomography (CT) scans. Carbon nanotube-based contrast agents offer superior imaging capabilities, including higher sensitivity and resolution, compared to conventional contrast agents.

Further research into carbon nanotubes for biomedical imaging has discovered that carbon nanotubes can be engineered to target specific biomolecules or disease markers. It has enabled early detection and diagnosis of various diseases, including cancer, cardiovascular disorders, and neurodegenerative diseases.

Challenges and Innovations

While carbon nanotubes hold immense promise for medical applications, several challenges must be addressed to realize their full potential. One of the primary concerns is the biocompatibility and safety of carbon nanotubes, as certain types of nanotubes may induce toxicity or inflammation in biological systems. Researchers are actively exploring strategies to mitigate these risks through surface modification, functionalization, and encapsulation of carbon nanotubes.

Despite attempts, however, challenges remain in achieving precise control over the synthesis, functionalization, and assembly of carbon nanotube-based materials for medical applications.

Environmental Impact

Carbon nanotubes have the potential to both positively and negatively impact the environment, depending on their applications and disposal methods.

Carbon Nanotubes and Sustainability

These nanotubes hold promise for promoting sustainability through various applications. For instance, carbon nanotube-based materials can enable the development of lightweight and durable products, leading to energy savings during transportation and reduced resource consumption.

Carbon nanotubes also show potential in renewable energy technologies, such as photovoltaics and fuel cells, where their unique properties can enhance device performance and efficiency. This further enables carbon nanotubes to facilitate environmental monitoring and remediation efforts by serving as sensors for detecting pollutants and as adsorbents for removing contaminants from air and water.

Overall, when used responsibly, carbon nanotubes have the potential to contribute to a more sustainable future by enabling innovative solutions to environmental challenges.

Ecological Concerns

Despite their potential benefits, carbon nanotubes also raise ecological concerns, particularly regarding their potential toxicity and environmental persistence. Studies have shown that certain types of carbon nanotubes may exhibit adverse effects on living organisms, including aquatic species and terrestrial organisms when released into the environment.

Moreover, the long-term environmental fate and behavior of carbon nanotubes remain poorly understood, raising concerns about their potential accumulation in ecosystems and food chains. The disposal of carbon nanotube-containing products at the end of their lifecycle presents challenges, as improper disposal methods could lead to the release of nanomaterials into the environment.

To address these concerns, researchers are investigating the environmental fate, behavior, and toxicity of carbon nanotubes, as well as developing strategies for the safe handling, use, and disposal of nanomaterials. FCC, through research on catalytic reaction control technology, is doing its part to reduce the emission of greenhouse gases and hazardous substances generated by industrial activities.

Learn More About Our Papermaking And New Materials Technology!

Future Perspectives

Moving forward, it is essential to adopt a proactive approach to mitigate the environmental risks associated with carbon nanotubes while harnessing their potential benefits. This includes conducting rigorous assessments of the environmental impacts of carbon nanotube-based products throughout their lifecycle, from production to disposal.

Efforts should be made to develop sustainable synthesis methods for producing carbon nanotubes, minimize waste generation, and promote the recycling and reuse of nanomaterials.

Advancements in Research

Advancements in carbon nanotube research continue to push the boundaries of scientific knowledge and technological innovation.

Current Research Frontiers

- Functionalization and Tailoring Properties: Researchers are actively exploring new methods for functionalizing carbon nanotubes to tailor their properties for specific applications. This includes surface modification techniques to improve dispersibility, biocompatibility, and interaction with other materials.

- Chirality Control: Controlling the chirality of carbon nanotubes remains a significant research frontier. Scientists are investigating novel synthesis methods and growth techniques to produce CNTs with precise chirality, which is crucial for unlocking their full potential in electronics and other fields.

- Energy Storage and Conversion: Advancements in carbon nanotube-based materials are driving research in energy storage and conversion technologies. This includes developing high-performance electrodes for batteries, supercapacitors, and fuel cells and exploring CNT-based catalysts for renewable energy applications.

- Biomedical Applications: Research in carbon nanotube-based biomedical applications continues to expand, with a focus on drug delivery systems, imaging agents, biosensors, and tissue engineering scaffolds. Efforts are underway to address biocompatibility, toxicity, and targeting efficiency to enhance the clinical translation of CNT-based therapeutics.

- Environmental Remediation: carbon nanotubes show promise for environmental remediation applications, such as water purification, pollutant sensing, and remediation of contaminated soil and air. Research in this area aims to develop cost-effective and scalable CNT-based technologies for addressing environmental challenges.

Breakthrough Discoveries

Collaboration between researchers, policymakers, industry stakeholders, and the public is crucial for addressing concerns and shaping responsible practices for the use of carbon nanotubes in a way that maximizes their benefits while minimizing potential risks to the environment and human health.

- Selective Synthesis of Chiral Carbon Nanotubes: Recent breakthroughs have enabled the selective synthesis of chiral carbon nanotubes with controlled properties, opening up new possibilities for applications in nanoelectronics and photonics.

- High-Performance Carbon Nanotube-Based Composites: Researchers have achieved significant advancements in the development of carbon nanotube-based composites with exceptional mechanical, electrical, and thermal properties. These materials hold promise for lightweight structural components in aerospace, automotive, and other industries.

- Biofunctionalized Carbon Nanotubes for Biomedical Applications: Breakthroughs in biofunctionalization techniques have led to the development of carbon nanotube-based platforms for targeted drug delivery, imaging, and cancer therapy. These discoveries are paving the way for personalized medicine and improved healthcare outcomes.

- Efficient Energy Storage Devices: Novel carbon nanotube-based electrode materials with high specific surface area and conductivity have been developed for energy storage devices, leading to improvements in battery performance, charging rates, and cycle life.

Collaborative Initiatives

Collaborative research initiatives involving multidisciplinary teams are driving innovation in carbon nanotube research. These initiatives bring together experts from academia, industry, and government agencies to address complex challenges and accelerate the development of carbon nanotube-based technologies.

- The National Nanotechnology Initiative (NNI): This US consortium fosters collaboration between researchers, industries, and governments to accelerate carbon nanotube research and development.

- European Graphene Flagship: This graphene flagship initiative brings together researchers across Europe to advance research and applications of graphene-based materials, including carbon nanotubes, with a focus on societal impact.

- National labs and universities: Collaborative research between institutions across the globe drives continuous breakthroughs and advancements in various aspects of carbon nanotubes research.

Conclusion

Throughout this exploration into “What are carbon nanotubes?”, we’ve uncovered the remarkable properties and diverse applications of carbon nanotubes (CNTs). From their unique structure and synthesis methods to their transformative impact across industries. Carbon nanotubes have emerged as a versatile and promising nanomaterial with the potential to revolutionize technology and address complex challenges.

Here at FCC, we are always exploring ways to provide value to our customers which is why we’ve partnered with Carbon Fly to advance their high-performance multi-walled carbon nanotube (MWCNT) development and to produce carbon nanotubes reinforced products together. It’s evident that the potential of these multiwalled carbon nanotubes is vast, but realizing this potential requires collective action and collaboration