Within today’s competitive industrial sector, Fortune 500 companies collectively lose 480 billion dollars annually due to inefficiencies in their processes. A key differentiating factor among the top performers is the strategic deployment of breakthrough methodologies for production process improvement.

As we delve into this blog post, we are set to explore a variety of innovative strategies for production process improvement. These proven methods have not only been instrumental in shaping the success of your company but also hold the potential to redefine operations in a multitude of industries. Here’s how to revolutionize and foster your production process improvement and skyrocket your business toward superior productivity and profitability.

Definition and Importance of Production Efficiency

Production efficiency, a fundamental concept in the field of operational management, is the optimal usage and allocation of resources in a production process. Essentially, it’s about achieving maximum output with minimum waste. The World Economic Forum, in its briefing paper, Advanced Manufacturing, emphasizes the significance of production efficiency, indicating that it’s a critical determinant of an organization’s effectiveness and competitiveness in the market.

Why is Production Efficiency Important?

The importance of production efficiency cannot be overstated.

Studies show that companies that prioritize production process improvement report an increase in profitability in comparison to their counterparts. Accenture attributes this surge in profitability mainly to the reduction of waste and redundant processes that lead to significant cost savings. Furthermore, production efficiency contributes to enhanced product quality, timely delivery, and customer satisfaction, instrumental in maintaining a company’s competitive edge.

Thus, understanding and applying strategies to boost production efficiency is not only beneficial but also crucial for businesses aiming to thrive in today’s fiercely competitive industrial landscape.

Current Challenges in Production Efficiency

The journey towards achieving optimal production efficiency is often lined with numerous hurdles. Below, we break down five major challenges standing in the way of business enterprises aspiring to boost their production efficiency:

- Inadequate Process Visibility: Many organizations lack a holistic view of their production processes. This lack of transparency often results in unidentified bottlenecks, inefficient resource allocation, and ultimately, underoptimized production.

- Obsolete Technology: Relying on outdated technology and machinery can significantly impede production process improvement, leading to frequent breakdowns, increased maintenance costs, and poor product quality. Investing in the latest technology is crucial for companies aiming to streamline their production processes. A great example of this is investing in innovative strategies for inventory management, especially if you are in the automobile industry.

- Inconsistent Quality Control: Inconsistent quality control can lead to significant waste in the form of defective products. Moreover, it may damage the company’s reputation and customer trust, leading to declining sales and profitability.

- Lack of Skilled Labor: The shortage of skilled labor is another significant challenge. Without competent and well-trained employees, even the most sophisticated machinery and processes may fail to deliver the desired efficiency.

- Resistance to Change: Lastly, organizations often face resistance from employees when implementing new methods or technologies aimed at improving production efficiency. This hurdle can be overcome by fostering an organizational culture that embraces change and encourages continuous learning.

Overcoming these challenges requires strategic planning, dedicated efforts, and a commitment to continuous improvement.

Understanding Key Metrics

Key metrics, also known as key performance indicators (KPIs), are quantifiable measures that organizations use to evaluate, analyze, and track their operational performance over time. In production, these metrics provide a numerical basis to assess and improve the efficiency and effectiveness of production processes, thereby facilitating production process improvement.

Leveraging key metrics in production allows organizations to identify areas of inefficiency, monitor progress toward operational goals, and make informed strategic decisions.

Benefits of Measuring and Analyzing Production Metrics

Measuring and analyzing production metrics offer numerous benefits. These quantitative data foster a culture of continuous improvement and accountability, guiding key stakeholders toward data-driven decision-making. Moreover, these metrics help pinpoint bottlenecks and inefficiencies, thus enabling targeted and effective process improvements. Companies that consistently track and measure their production metrics are more likely to exceed their productivity goals, underscoring the immense value of these operational metrics.

Examples of Production Metrics and Their Interpretation

Here are a few examples of production metrics that you can also utilize:

- Overall Equipment Effectiveness (OEE): OEE is a comprehensive metric that measures the efficiency and productivity of a production process. It takes into account three crucial elements of manufacturing: availability, performance, and quality. A high OEE score indicates that a manufacturing process is highly efficient and productive, whereas a low score suggests areas for improvement.

- Cycle Time: Cycle time refers to the total time it takes to complete one production cycle. By tracking this metric, organizations can identify bottlenecks in their production process and work towards reducing cycle times, thereby boosting productivity and efficiency.

- Scrap Rate: The scrap rate measures the percentage of produced materials that do not meet the required quality standards and hence are discarded. A high scrap rate could indicate issues with the production process, materials, or machinery, necessitating further investigation and corrective action.

By understanding and leveraging these key production metrics, organizations can effectively navigate the road to heightened production efficiency.

Technology Integration

The advent of technology has introduced novel and game-changing approaches to enhancing production efficiency. In particular, automation and the Internet of Things (IoT) are driving massive improvements in production processes. These technologies provide real-time monitoring capabilities, enhancing visibility and control over every stage of production.

Automation in Production Processes

Automation, the use of technology to perform tasks without human intervention, has revolutionized production processes across industries. According to a McKinsey report, companies that automate their operations can achieve a 15-20% increase in production output. This is made possible by the ability of automated systems to work continuously without fatigue, performing tasks faster and with fewer errors compared to human labor. Additionally, automation frees employees to focus on higher-value tasks requiring creativity and problem-solving skills, thus promoting innovation and productivity.

IoT and Real-time Monitoring

The Internet of Things (IoT), a network of interconnected devices that communicate and share data, is a significant driver of improvements in production efficiency. By equipping machines and equipment with IoT sensors, businesses can collect real-time data on various parameters of the production process. A research article in the Journal of Industrial Information Integration highlights that IoT adoption in manufacturing leads to an increase in productivity. Real-time monitoring enables quick identification and resolution of issues, minimizes downtime, and enhances product quality. Furthermore, the data generated by IoT devices provide valuable insights that can inform strategic decisions for production process improvement.

Employee Training and Engagement

Workforce competency and motivation are critical drivers of production efficiency. A skilled and engaged workforce can significantly enhance productivity and foster a culture of continuous improvement.

Continuous Skill Development Programs

Investing in continuous skill development programs is a proven strategy to enhance the efficiency and productivity of the workforce. These programs may include technical training, soft skill development, and leadership training. They equip employees with the necessary skills to excel, adapt to new technologies, and work more efficiently. According to a study by the American Society for Training and Development, companies that offer comprehensive training programs have a 218% higher income per employee than companies without formalized training.

Creating a Culture of Efficiency

Creating a culture of efficiency involves fostering an environment where employees are encouraged to seek out and implement process improvements. This can be achieved by promoting transparency, rewarding efficiency-focused behavior, and encouraging collaboration and innovation.

Research by Gallup shows that companies with highly engaged workforces outperform their peers by 147% in earnings per share, highlighting the immense value of a culture that prioritizes efficiency. In such a culture, employees understand the importance of efficiency to the organization’s success and are motivated to seek ways to improve production processes continuously.

Lean Manufacturing Principles

Transitioning beyond technology and employee engagement, another method that is widely recognized for its ability to boost production efficiency is the adoption of lean manufacturing principles. This approach focuses on minimizing waste within a manufacturing system while simultaneously maximizing productivity.

Overview of Lean Manufacturing

Lean Manufacturing, also known as Lean Production, is a systematic approach to waste reduction in manufacturing processes. It primarily involves identifying non-value-adding activities and systematically reducing or eliminating them. According to a study, manufacturers employ a lean manufacturing strategy to improve their operations. The core idea of lean manufacturing is to produce exactly what is needed, when it is needed, with as little waste as possible.

Implementing Lean Techniques in Production

Practical implementation of lean techniques in production begins with a thorough understanding of the seven wastes of lean:

- overproduction

- waiting

- transport

- over-processing

- inventory

- movement

- and defects.

It’s important to identify and eliminate these wastes to create more value with fewer resources. Lean tools like Kanban, Value Stream Mapping, and 5S are often used to accomplish this. For instance, a study by the American Society of Quality found that implementing the 5S methodology led to significant improvements in organizational cleanliness, better morale, and increased performance. By understanding and properly implementing these lean techniques, manufacturing companies can significantly enhance their production efficiency.

Data-Driven Decision Making

In a digital age, where information is key to improvement and innovation, leveraging data-driven decision-making proves invaluable. The use of big data analytics and predictive modeling provides profound insights that can further enhance production efficiency.

Utilizing Big Data Analytics

Big Data analytics refers to examining large and varied data sets, or “big data”, to uncover hidden patterns, correlations, and other insights. It enables manufacturers to understand production trends, identify bottlenecks, and make informed decisions. For instance, according to a study by Accenture, 79% of enterprise executives agree that companies that do not embrace Big Data could face extinction.

Predictive Modeling for Production

On the other hand, predictive modeling uses data and statistical algorithms to determine the likelihood of future outcomes based on historical data. It’s essentially about forecasting what might happen in the future. For example, predictive models can forecast production downtime, which can be addressed proactively to avoid significant disruptions. A McKinsey report suggests that predictive maintenance could reduce machine downtime by 30-50% and increase machine life by 20-40%. This underscores the transformative potential of predictive modeling in enhancing production efficiency.

Supply Chain Optimization

Another important piece of the puzzle for maximizing production efficiency lies in supply chain optimization. A well-managed supply chain can substantially increase a company’s operational efficiency and customer satisfaction levels.

Streamlining the Supply Chain

Streamlining the supply chain involves enhancing the flow of materials and information from the suppliers to the customers. This can be achieved through process improvement, technology integration, and performance measurement. According to a survey by Deloitte, 79% of companies that excel in supply chain performance achieve revenue growth greater than their industry average. Effective supply chain streamlining can lead to reduced lead times, minimized errors, and improved customer satisfaction, all of which contribute to increased production efficiency.

Collaborative Planning with Suppliers

Collaborative planning with suppliers is another influential method of optimizing the supply chain. This approach entails sharing information and working together with suppliers to improve supply chain performance. Collaborative planning can lead to improved forecast accuracy, reduced inventory levels, and enhanced service levels. Collaborative supply chain practices can lead to a significant enhancement in operational performance. By fostering strong collaborative relationships with suppliers, organizations can ensure a steady and reliable supply of materials, thereby enhancing their overall production efficiency.

Sustainability Practices

In the face of pressing environmental issues, the adoption of sustainable practices in manufacturing is no longer just a choice, but a necessity. It involves integrating these green initiatives into our manufacturing processes.

Green Production Initiatives

Green production initiatives encompass practices that reduce waste and minimize environmental impact. This can include energy-efficient machinery, reduction in hazardous emissions, or the implementation of recycling and waste management programs. Such initiatives not only improve production efficiency but also help in conserving our environment.

Eco-friendly Materials and Processes

The use of eco-friendly materials and processes is another crucial aspect of sustainable manufacturing. This involves choosing raw materials that are renewable or have minimal environmental impact and implementing processes that minimize waste. For instance, advanced manufacturing technologies can reduce material waste significantly.

Quality Control Strategies

As we strive for efficiency, we must not overlook the importance of quality. Effective quality control strategies are crucial to maintaining high production standards and ensuring customer satisfaction, all key areas of production process improvement.

Implementing Total Quality Management (TQM)

Total Quality Management (TQM) is a holistic approach that focuses on improving the quality of products and services through ongoing refinements in response to continuous feedback. TQM requires the involvement of all departments and employees and necessitates the integration of quality principles into every facet of the company’s operations. Leading-quality organizations are more likely to use dedicated quality teams and more likely to assign individual responsibility for quality.

Continuous Improvement in Quality Assurance

Continuous improvement in quality assurance refers to the ongoing effort to improve products, services, or processes. This is in hopes of seeking gradual improvement over time or breakthrough improvement all at once. Through the ongoing improvements of organizational processes, efficiency and effectiveness are improved leading to high-quality products. The American Society for Quality reports that organizations that implement continuous improvement practices can significantly enhance their profitability and long-term financial stability. It’s not simply about catching defects but developing a culture of continuous improvement that permeates every level of the organization.

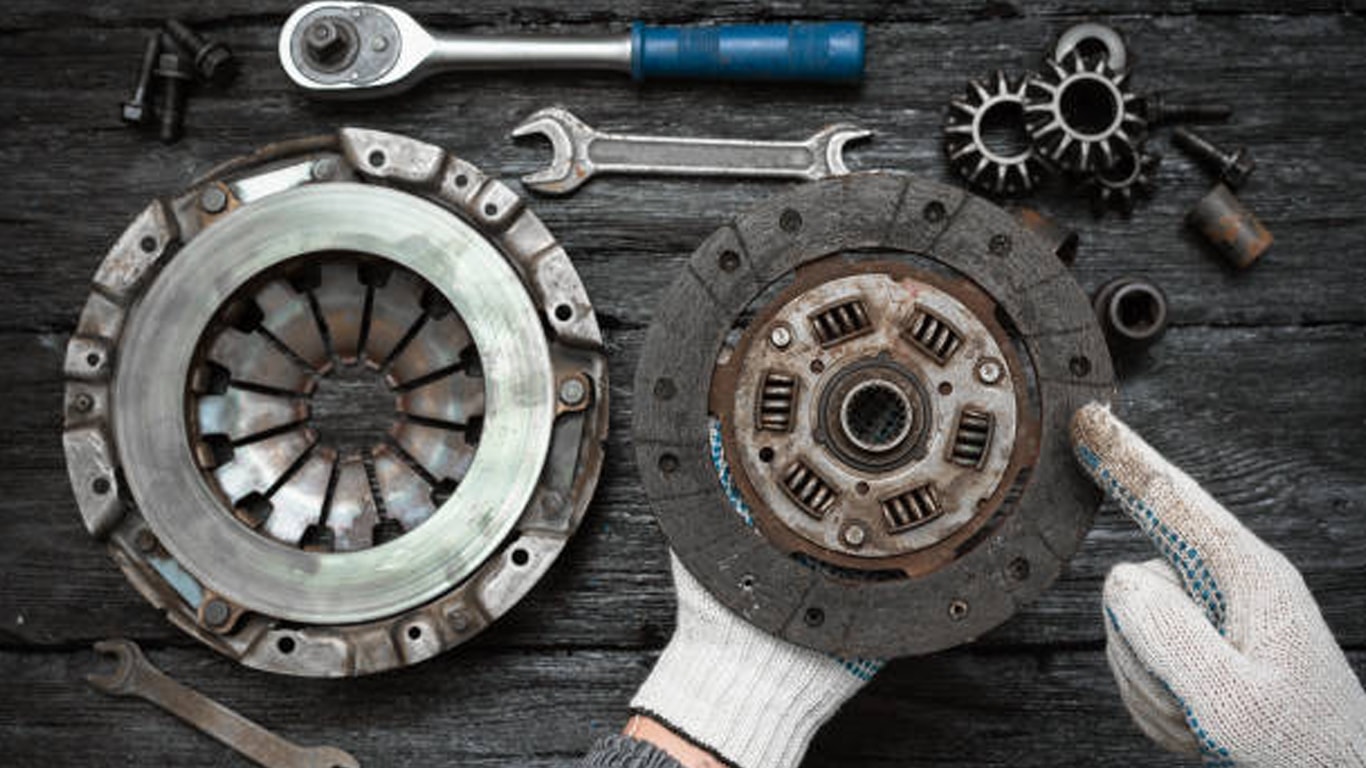

FCC is unwavering in its commitment to innovation and superior quality, striving relentlessly to deliver the finest products in the automotive and motorcycle clutch industry. Our relentless pursuit of innovative technologies and stringent quality control strategies underlines our dedication to operational excellence and customer satisfaction.

Ready To Explore Innovative Solutions To Boost Production Efficiency Today?

Cross-Functional Collaboration

Production efficiency is not just about technology, machinery, or processes, it’s also about the people who drive these elements. Therefore, the role of cross-functional collaboration in enhancing production efficiency cannot be overstated.

Breaking Silos in Production Teams

Breaking down silos in production teams is vital for fostering a collaborative work environment. Silos breed isolation and hinder the free flow of information, ideas, and innovation. According to a study by McKinsey, when social technologies are used to enhance communication and collaboration within organizations, they can raise the productivity of high-skill knowledge workers by 20-25%. Therefore, breaking down these silos can significantly boost productivity, enhance problem-solving capabilities, and stimulate innovation, all of which contribute to improved production efficiency.

Enhancing Communication Across Departments

Enhancing communication across departments is key to fostering a holistic understanding of the production process. Effective interdepartmental communication ensures all teams are aligned towards a common goal and are aware of their role in the larger scheme of production process improvement. According to a study by the Project Management Institute, inadequate or poor communication has been identified as the primary contributor to project failure one-third of the time and harmed project success more than half the time. A culture of open, frequent, and multidirectional communication can significantly enhance production efficiency by facilitating quicker decision-making, reducing misunderstandings and errors, and boosting employee morale and engagement.

Smart Factory Implementation

In the era of Industry 4.0, as we digitally transform traditional manufacturing and industrial practices, the concept of a smart factory becomes increasingly pertinent. The smart factory represents a leap forward from more traditional automation to a fully connected and flexible system—one that can use a constant stream of data from connected operations and production systems to learn and adapt to new demands.

Industry 4.0 and Smart Manufacturing

Industry 4.0, also known as the Fourth Industrial Revolution, is marked by the emergence of new digital industrial technology. Smart manufacturing, a major element of Industry 4.0, is a fully integrated, collaborative manufacturing system. It responds in real time to changing demands and conditions in the factory, in the supply network, and in customer needs. Smart manufacturing employs computer controls, modeling, big data, and other automation to improve manufacturing efficiencies. According to Deloitte Insights, companies implementing Industry 4.0 technologies have seen an improvement in operational efficiency.

Integrating Smart Technologies in the Production Floor

Incorporating smart technologies into the production floor typically involves the use of Internet of Things (IoT) devices, Artificial Intelligence (AI), robotics, and advanced data analytics tools. These technologies can automate and optimize the production line, enhance predictive maintenance, reduce downtime, and enable real-time inventory management. According to PWC, companies that are heavily investing in digital technologies for their factories expect efficiency gains of 12% over the next five years. This underscores the potential of smart technologies to enhance production efficiency.

Capacity Planning

As we dive deeper into the methods for boosting production efficiency, it becomes evident that strategic management of resources through capacity planning is a critical component.

Balancing Workloads and Resources

Balancing workloads and resources is a crucial aspect of capacity planning, aimed at optimizing the use of manpower, materials, and machines. It involves ensuring that workloads are evenly distributed, preventing overutilization or underutilization of resources. A well-balanced system promotes efficiency, reduces waste, and enhances overall productivity. As evidence, the Harvard Business Review found that effective workload balancing led to improved overall performance in a variety of industries.

Forecasting for Production Scaling

Forecasting for production scaling is another critical aspect of capacity planning. This involves predicting future production needs based on current data and market trends to ensure that resources can be scaled up or down as needed. Effective forecasting minimizes the risk of production interruptions due to resource shortages and prevents the wastage of idle resources. Companies that excel in their forecasting activities have 15% less inventory, 17% stronger perfect order fulfillment, and 35% shorter cash-to-cash cycle times, reinforcing the significance of accurate forecasting in enhancing production efficiency.

Summary

Innovative ways for production process improvement are certainly within reach. From breaking down departmental silos to enhancing communication, implementing smart factories, and effective capacity planning, there are myriad strategies to maximize productivity and success.

At FCC, we are at the forefront of these advancements. Our commitment to quality, innovation, and efficiency makes us a trusted partner in the automotive and motorcycle clutch industry. If you’re ready to benefit from these innovative solutions in your business, don’t hesitate to connect with us today. Together, we can drive your production efficiency to new heights.

Ready To Explore Innovative Solutions To Boost Production Efficiency Today?